Jodee from Inspire Woodcraft shared the woodworking tip featured in this video.

This short video demonstrates a simple, reliable way to find miter angles using only two equal-width scrap pieces and a pencil mark instead of measurements or tools.

The method works for inside and outside corners and for both obtuse and acute angles, making on-site trim work faster and less intimidating.

Watch the full video and subscribe to Jodee’s channel:

The simple scrap-piece method

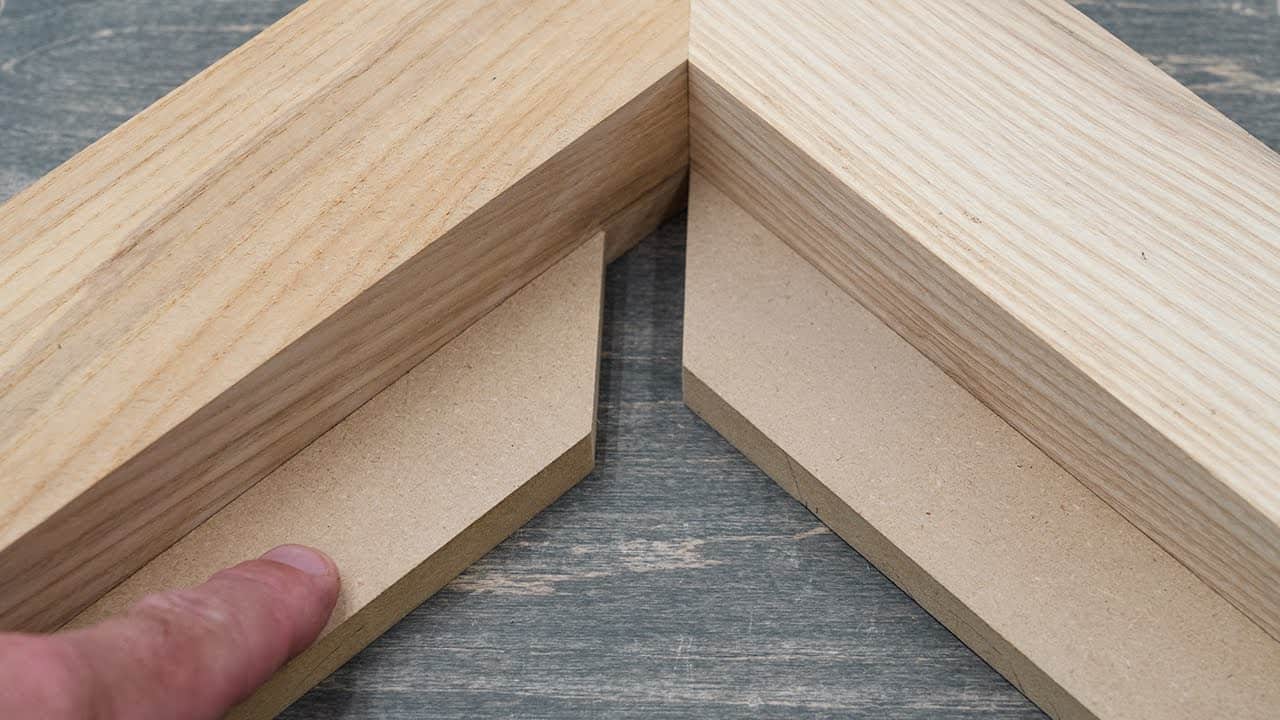

The core idea is to use two scrap boards of the same width as a makeshift angle finder by positioning them against the walls and marking where they meet. Connecting those marks gives the cut line for both pieces so they will meet cleanly at the corner when cut the same way.

This technique eliminates measuring and calculating angles, and it translates directly to the saw by simply cutting both mating pieces to the same line. The method is flexible enough to handle different trim widths and irregular walls because the scraps register against the actual surfaces rather than relying on theoretical angles.

Inside corners

For an obtuse inside corner, slide one scrap into the corner and hold the second scrap against the opposite wall, then mark where the two meet and draw a line to define the cut. Cutting both pieces to that line produces a miter that fits the actual corner without any math or protractors.

Acute inside corners can create a small gap if the scrap ends are square, so Jodee suggests beveling the scrap end slightly before marking to let it seat tight into the corner. A small, consistent bevel on the scrap allows a snug fit and the same marking approach produces the needed angle for both mating pieces.

Outside corners

For obtuse outside corners, press each scrap against its respective wall, note where they overlap, and mark those points; linking the marks produces the miter cut needed for the outside joint. Cutting both trim pieces to that line ensures they will meet cleanly when installed on the corner.

Acute outside corners follow the same principle: hold the scraps in place where the trim will sit, mark the overlap points, and connect them to create the cut line. The simplicity of marking on the actual surfaces avoids the trap of assuming corners are perfect 90-degree angles.

Tips, accuracy, and adaptability

Accuracy depends mostly on how carefully the marks and lines are drawn, so taking a moment to hold the scraps steady and scribe clear points will improve the fit. Matching the width of the scraps and trimming any burrs or irregularities beforehand helps the method be repeatable and reliable.

The technique adapts to many on-site conditions because it references the real corner, not a calculated angle; this reduces wasted material and guesswork. It also works for a range of trim profiles and materials since the principle is simply transferring the joint geometry from the wall to the workpieces.

Why this trick matters

This is a practical solution for hobbyists and pros who want to cut accurate miters without fancy tools, math, or measuring jigs. It reduces setup time, minimizes errors from out-of-square walls, and keeps the focus on a quick mark-cut-test workflow that fits typical trim work.

Because the method scales with the width and shape of the trim, it can be incorporated into many projects where speed and reliability matter more than exact angle reporting. The technique is especially useful when dealing with imperfect conditions or when a simple, visual approach is preferred.

Jodee’s scrap-piece method is a useful, low-tech approach that simplifies miter fitting and reduces wasted time and material; it is easy to adopt and adapt across a wide range of trim and finish situations.

Support Jodee by visiting his online store here: https://inspirewoodcraft.com/collections/all.

Matt’s Take

These are my personal thoughts and tips based on my own experience in the shop. This section is not written, reviewed, or endorsed by the original creator of this project.

This scrap-piece method is one of those shop tricks that feels almost too simple to work, but it’s incredibly effective. The beauty is that it eliminates the whole chain of potential errors — measuring the angle, calculating the miter, setting up the saw — and replaces it with direct transfer from the actual corner to your workpiece.

One thing I really appreciate about this approach is how it handles the reality that very few walls meet at perfect 90-degree angles. When you’re doing trim work, especially in older homes, trying to use calculated angles often leads to gaps and frustration. This method automatically compensates for whatever angle actually exists.

The accuracy really does come down to careful marking, as Jodee mentions. I’d add that using a sharp pencil or even a knife for scribing can make a big difference in the final fit. Also worth noting — this technique works great for crown molding and other complex profiles where the actual contact points might not be obvious just from looking at the corner.

For anyone hesitant about miter work, this is a game-changer. It takes the intimidation factor out of trim carpentry and lets you focus on making clean cuts rather than wrestling with angle calculations. Sometimes the best solutions are the simplest ones.