This project was built and designed by Norman Pirollo from WoodSkills.

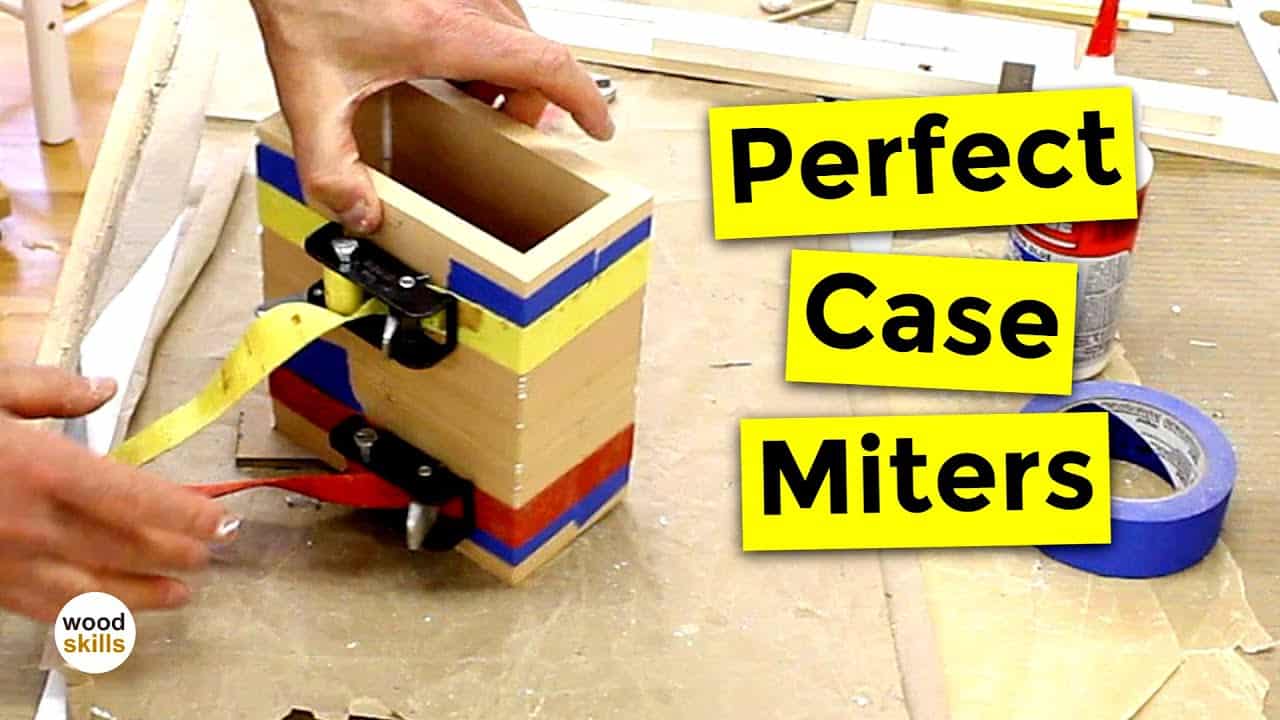

It focuses on precise miter joinery using traditional hand tools, showcasing Norman’s refined approach to building clean, professional boxes with tight-fitting corners.

Rather than relying on power tools or complex jigs, Norman uses a shooting board and careful planning to achieve perfect results.

The method is ideal for anyone looking to improve their joinery skills, particularly in fine woodworking or small box making.

Watch the full video and subscribe to Norman’s channel:

Why Case Miters Matter

Case miters are the angled joints you often see on the corners of boxes and drawer units. They provide both visual appeal and structural integrity, but they’re also notoriously difficult to get just right.

Norman emphasizes the importance of a clean, gap-free miter. These joints must be precise not just for looks, but also to ensure long-term strength and alignment across all parts of the box.

Getting Started with Rough Cutting

The process begins with roughing out the four side components of the box. These are cut to roughly 45 degrees using a bandsaw, though a slight variation from 44 to 46 degrees is acceptable.

What matters more than perfect angles at this stage is consistency between the pieces.

Norman stresses the need to keep all parts flat and in the same plane, laying the foundation for accurate joints later on.

Fine-Tuning Each Miter Joint

After rough cutting, each miter is refined using a shooting board. This jig allows Norman to trim tiny amounts off each joint face, checking for fit and adjusting as needed.

This technique gives more control than a power saw, especially when dealing with small, thin stock.

By testing the fit frequently and working in small increments, Norman ensures each corner closes tightly without gaps.

Measuring and Adjusting Components

As the parts are shaped, they’re compared side-by-side to ensure matching lengths.

Even a small discrepancy can result in misaligned edges or open joints, so Norman checks repeatedly with measuring tools and layout squares.

When something is slightly off, it’s corrected on the shooting board. The goal is not to force the pieces together, but to shape them until they naturally meet with precision.

Using Reference Parts for Layout

The dimensions of this box are based on existing drawer components, which guide the overall proportions.

Using reference parts helps maintain consistent sizing and ensures the final piece integrates well with other furniture or storage elements.

This also minimizes guesswork. Instead of starting from scratch, Norman lets existing components dictate cut lengths and spacing, streamlining the build process.

Fitting the Top and Bottom Panels

With the miters dialed in, the next task is to create the top and bottom panels. These are cut to fit inside the box once it’s assembled, so exact sizing is essential.

Norman trims each panel carefully, checking fit within the frame. Panels should slide in snugly without forcing or leaving gaps—tight enough to hold in place, but not so tight that they distort the sides.

Correcting Minor Imperfections

Despite the precision of the process, small imperfections are inevitable. Sometimes a corner may chip slightly during trimming, or a board may have a minor curve from planing.

Rather than discarding parts, Norman explains how to work through these issues. Slight chipping can be cleaned up after glue-up, and internal irregularities are often hidden in the finished box.

This is part of the hand tool mindset: do your best, then refine as needed. Small fixes are part of the craft and rarely detract from the final result.

Why Use a Shooting Board?

The shooting board is one of the most important tools in Norman’s process. It allows safe, accurate trimming of angled joints and works especially well for small parts.

Compared to power saws, which can struggle with narrow stock or require complex jigs, a shooting board is simpler, quieter, and more tactile.

It encourages a methodical workflow and provides excellent control.

Norman also notes that a shooting board can be customized for specific angles, making it a versatile addition to any hand tool shop.

Tips for Success

Norman offers several key insights throughout the build:

- Work in small increments when trimming to avoid over-cutting.

- Measure often, using a reliable square or angle gauge to verify accuracy.

- Use reference parts for layout when available to ensure consistency.

- Don’t rush—tight miters come from careful, patient work.

These habits make a big difference, especially when working with traditional tools. The attention to detail builds confidence and results in cleaner, stronger joints.

A Project That Builds Skill and Confidence

Making a wooden box with perfect case miters is both a technical challenge and a great learning experience.

It pushes woodworkers to think about accuracy, layout, and technique in a focused way.

Norman’s approach combines careful planning with traditional hand tool craftsmanship. His use of the shooting board highlights a valuable method for anyone serious about improving their joinery skills.

Watch the full video and subscribe to Norman’s channel:

Matt’s Take

These are my personal thoughts and tips based on my own experience in the shop. This section is not written, reviewed, or endorsed by the original creator of this project.

Case miters are one of those joints that really separate the beginners from the more experienced woodworkers. They look simple enough, but getting them to close perfectly without gaps takes patience and the right approach. Norman’s emphasis on using a shooting board is spot-on — it’s honestly one of the best investments you can make for precise joinery work, especially when dealing with smaller stock like this.

The incremental trimming approach Norman uses is key here. I see a lot of folks try to rush this process, taking off too much material at once and then having to start over. Working in tiny increments might feel slow, but it’s actually faster in the long run because you’re not constantly backtracking. That shooting board gives you the control to sneak up on the perfect fit, which is exactly what these joints demand.

Safety-wise, working with hand tools on small pieces like this is generally much safer than trying to wrestle thin stock through a table saw with complex miter sleds. The shooting board keeps your hands well away from the cutting edge while giving you that tactile feedback you need to feel when the joint is just right. Plus, there’s something satisfying about the quiet, methodical process that you just don’t get with power tools screaming in your ear.