This project, created by Fisher’s Shop, offers a unique approach to crafting a push stick that not only looks good but functions exceptionally well. Below is a detailed guide to making Drew’s push stick, complete with materials, tools, and step-by-step instructions.

Materials and Tools

- Ash, Bird’s Eye Maple, and Mahogany

- Walnut (for the base)

- Craft adhesive

- 5-minute epoxy

- Graphite shavings

- Danish oil

- Router with 1/8″ round over bit

- Band saw

- Miter saw

- Crosscut sled

- Spindle sander

- X-Carve for engraving logos

- Sanding block

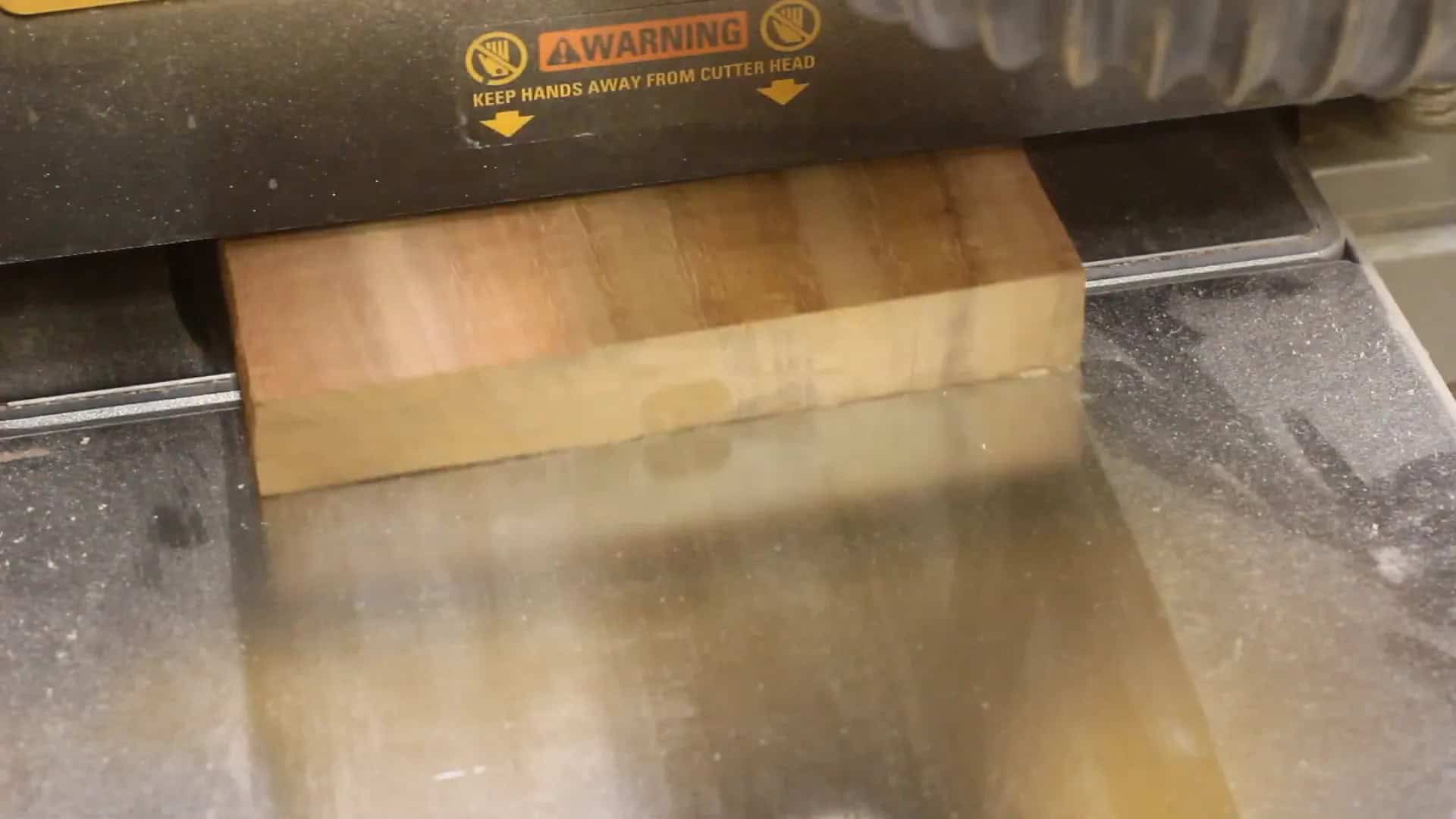

Step 1: Dimensioning the Wood

The first step is to dimension down the wood. Drew starts with some ash, Bird’s Eye Maple, and mahogany, which adds character to the push sticks. Next, he prints off a template multiple times and cuts out the shape for about half a dozen push sticks.

Step 2: Cutting the Shapes

Once the shapes are cut out, Drew applies craft adhesive to stick them onto the boards, maximizing the use of each piece. He then moves over to the band saw to cut out the shapes. He reassures that any wonky cuts can be cleaned up later, so there’s no pressure to be perfect right away.

Step 3: Trimming and Smoothing

After cutting, Drew uses the miter saw to nip off the back side of each stick, creating a flat surface. He then clamps the sticks on his crosscut sled to trim the bottom. The next task is to smooth things out using a spindle sander, removing any band saw marks.

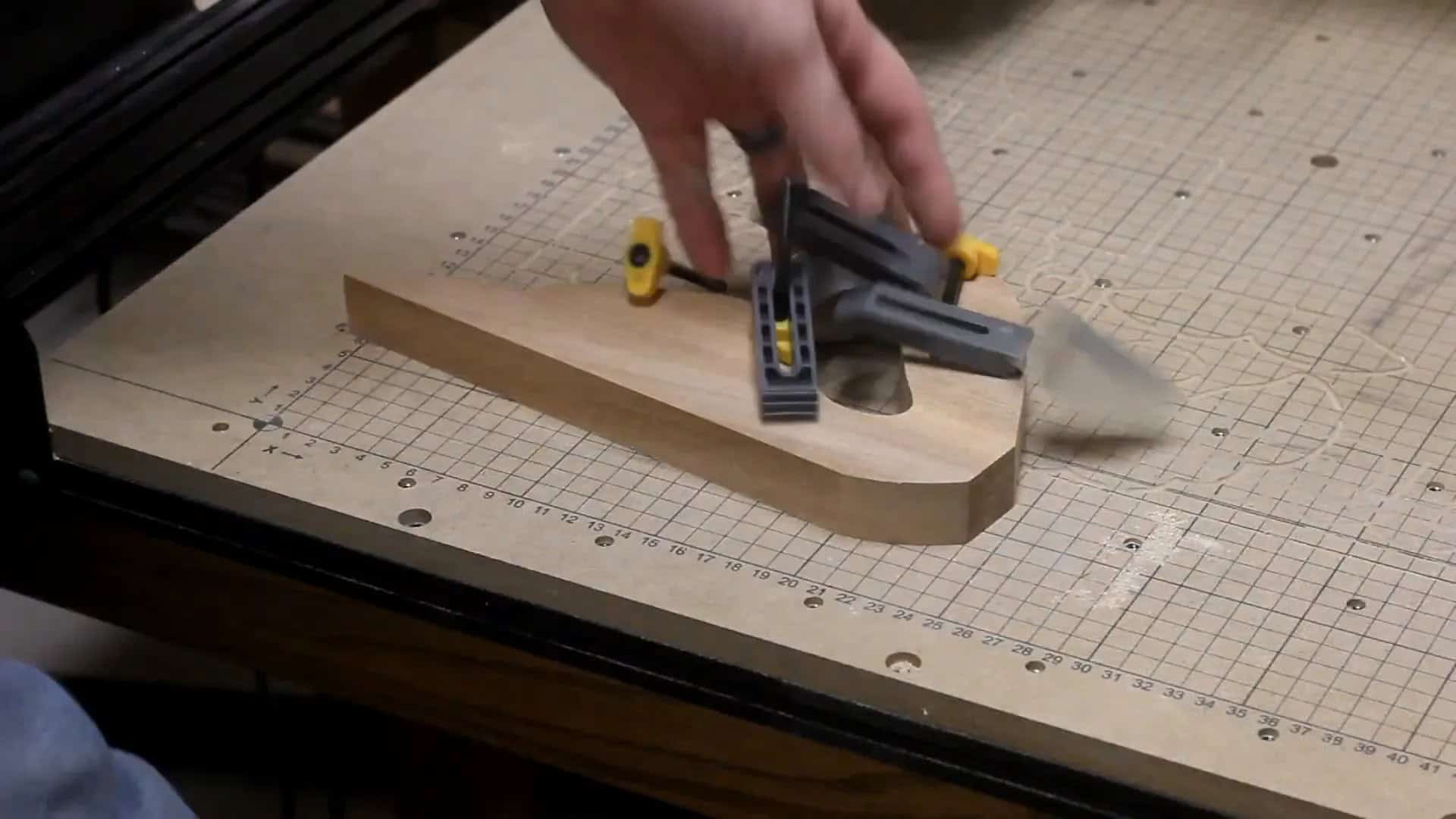

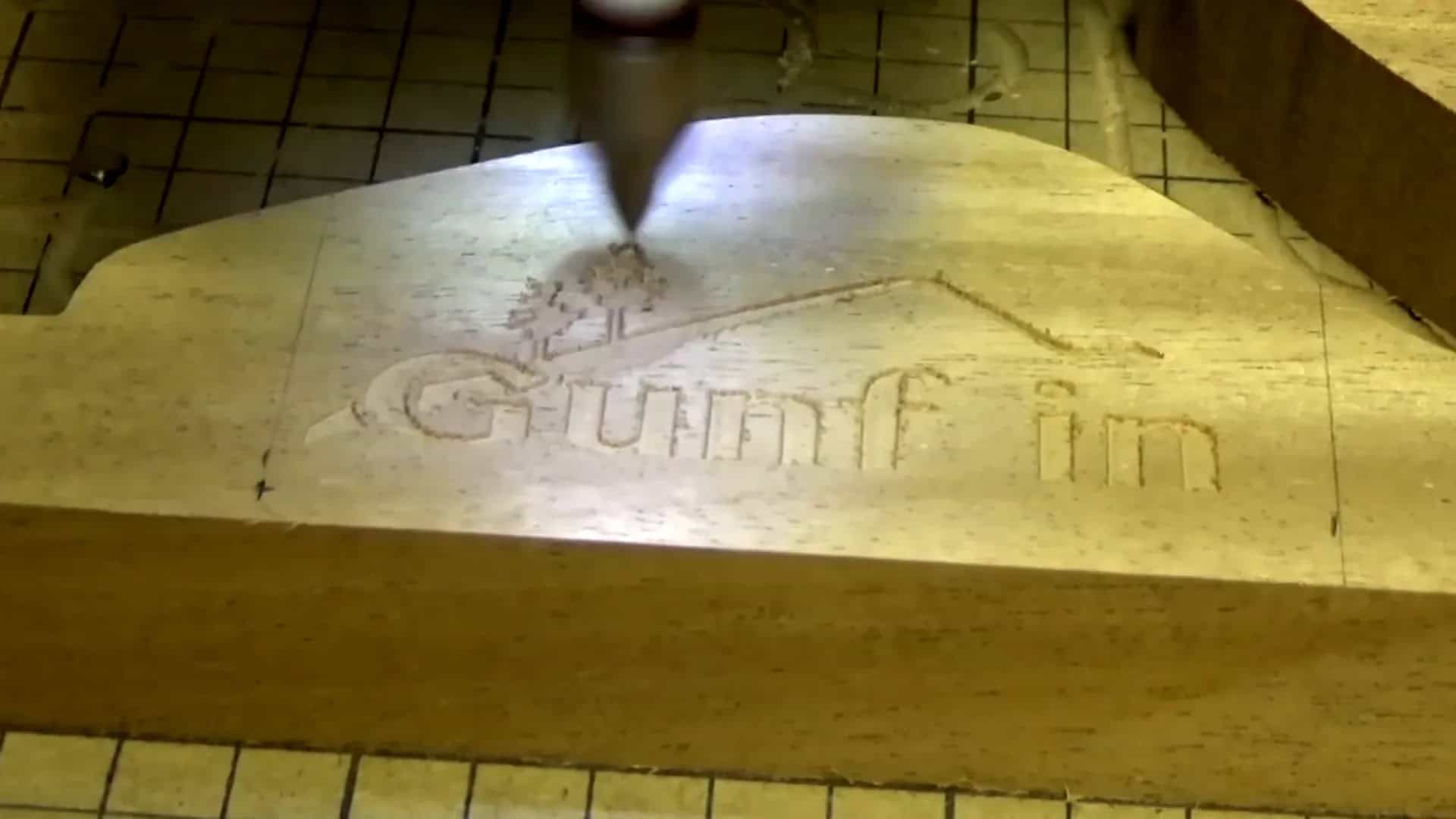

Step 4: Personalizing the Sticks

To add a personal touch, Drew engraves his friends’ logos into the sides using the X-Carve. He carefully measures the size of each logo and positions it before starting the engraving process. After a successful first logo, he proceeds to engrave his logo and his podcast logo on the remaining sticks.

Step 5: Applying Epoxy

Next, Drew squirts out some 5-minute epoxy and mixes in a tiny bit of graphite shavings for color. He applies the epoxy into the engraved logos, ensuring it fills all the cracks. He humorously notes the importance of timing, as the epoxy sets quickly. If bubbles arise, a blowtorch can help pop them.

Step 6: Sanding and Finishing

Once the epoxy cures overnight, he sands each stick lightly with 120 grit sandpaper, careful not to sand off any logos. He uses a router with a round over bit to soften the edges, while leaving the bottom and back square for better grip.

Step 7: Creating the Bases

Drew then cuts down pieces of walnut for the bases, ensuring they look sharp since these sticks are gifts. He spreads glue on the back edge, squares it up, and clamps it while drying. After the glue sets, he cuts a bird’s mouth into the tip of each stick to make it more functional.

Step 8: Adding the Catch Block

The upward curve at the back of the push stick allows for easy attachment of a new catch block. Drew emphasizes that this design helps replace the catch block easily as it gets worn out, adding to the longevity of the push stick.

Step 9: Final Touches

To enhance the aesthetics and feel, he adds a small chamfer to some edges with a sanding block, making them more aerodynamic. He finishes with several coats of Danish oil, which not only protects but also makes the wood grain pop.

Step 10: Using the Push Stick

Drew wraps up by demonstrating how the design allows for easy reuse. When the base and back catch get chewed up, simply clamp it down and clean off the bottom edge to glue on a new catch. This ensures the push stick remains functional over time.

This push stick design not only provides safety while working with saws but also allows for personal touches that make each stick unique. If you’re interested in making your own, Fisher encourages downloading the free template available on his website. Happy woodworking!