This project was built and designed by Steve from JKM Woodworking. It’s a handcrafted wine bottle cabinet and bar featuring solid cherry wood, clean joinery, and several thoughtful elements including wine bottle racks, glass holders, solid doors, and a custom drawer box.

The design blends elegance and function, offering storage, organization, and style in one refined package. Steve walks through every step with precision and care, making this an excellent example of detailed furniture making.

Watch the full video and subscribe to Steve’s channel:

Planning the Build with SketchUp

Before making the first cut, Steve maps out the entire project in SketchUp. This digital planning step helps visualize the final piece, refine proportions, and produce a reliable cut list.

Having a solid plan from the start makes the rest of the build more efficient. It ensures that all pieces are accounted for and that material usage stays optimized.

Constructing the Cabinet Frame

The cabinet body is built from ¾-inch cherry plywood. Steve begins by breaking down full sheets into manageable panels using a circular saw, followed by final sizing on the table saw.

To avoid chipping the cherry veneer, each panel is first scored with a shallow cut. This small step goes a long way toward maintaining clean edges and preserving the surface quality.

Applying Edge Banding

Once panels are cut, Steve uses iron-on cherry edge banding to cover the exposed plywood edges. A special trimming tool is used to flush the banding to the surface, giving each panel a finished look that blends well with the solid wood components.

The combination of plywood and solid accents helps control costs while maintaining a high-end appearance. The edge banding makes the plywood nearly indistinguishable from solid wood.

Joinery with Dados and Pocket Screws

To assemble the case, dado joints are cut using a dado stack on the table saw. Matching the settings for each pair of panels keeps everything aligned. For added flexibility, Steve also uses a router for shallower joinery when needed.

Glue, screws, and pocket holes come together to create a strong structure. A jig is used to drill pocket holes for cross supports, which help stiffen the cabinet and add overall integrity.

Enhancing the Base with a Toe Kick

To finish the base of the cabinet, a solid cherry toe kick is added. Mitered corners give it a clean appearance, while the bandsaw is used to add a subtle decorative detail.

This section grounds the cabinet visually and elevates the body off the floor. It also helps distribute weight more evenly, especially when loaded with bottles and glassware.

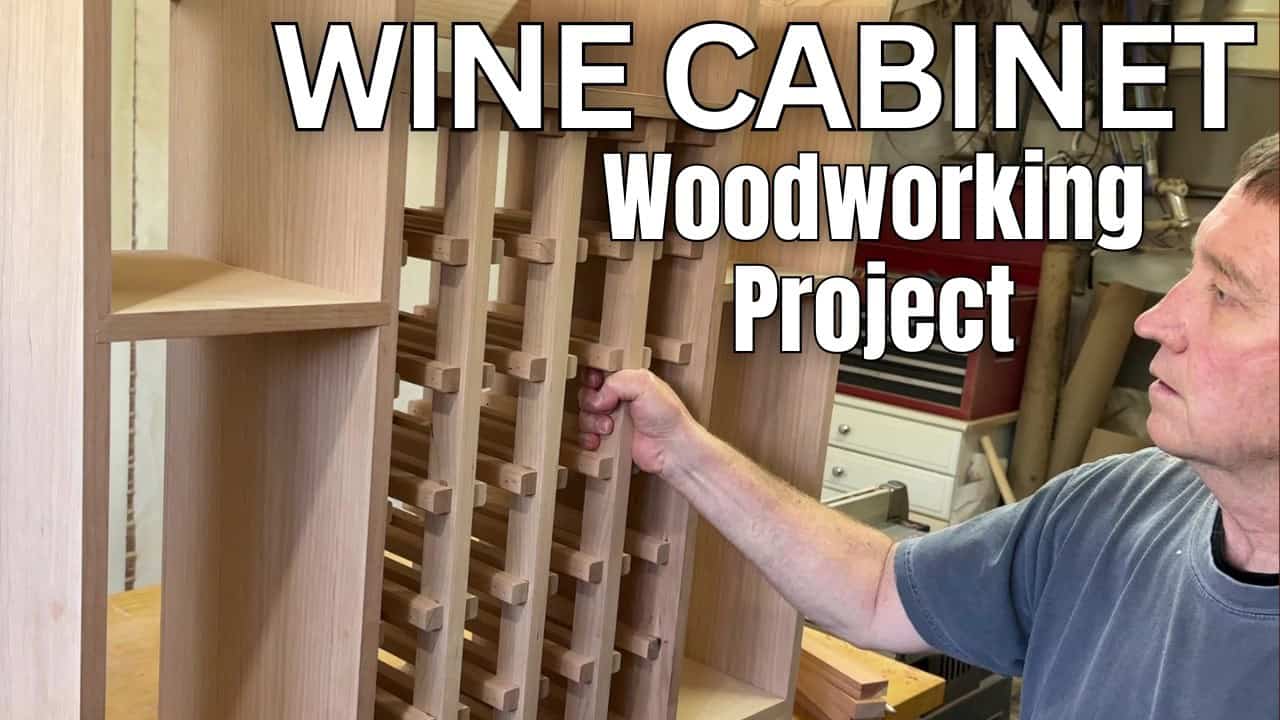

Building the Wine Bottle Rack

The wine rack section is made from solid cherry boards. One edge is jointed flat, and the other is made parallel on the table saw. A thin rip jig is used to safely cut the narrow slots that hold the bottles.

After sanding, a router table is used to chamfer the edges for a cleaner look and smoother handling. A stop block ensures each piece is cut to the same length, maintaining a consistent layout across the rack.

Creating Shaker-Style Cabinet Doors

For the doors, Steve uses a router bit set specifically designed for shaker-style construction. A groove is cut into the rails and stiles, and the tongue is carefully matched to fit cleanly into each groove.

The center panels are made by resawing thicker cherry stock, then planing them to the exact thickness needed. Once glued up, the panels are flush, clean, and ready for assembly.

Building a Durable Drawer Box

The drawer box is made from ½-inch cherry plywood, joined together with box joints. Steve uses a dedicated jig for accuracy, producing clean, interlocking corners that hold up well over time.

A groove is cut in all four sides to hold the drawer bottom. To minimize cleanup, painter’s tape is applied near the joints to catch glue squeeze-out during assembly.

Making the Wine Glass Holders

The final component is the wine glass holders, cut from solid stock on the table saw. A scrap wood spacer increases safety while cutting the thin slots for the glass stems.

After shaping, the holders are glued into place beneath a shelf. These small but useful details add functionality and elegance to the overall design.

Staining and Finishing with Shellac and Gel Stain

Finishing begins with a light coat of shellac to reduce blotchiness in the cherry wood. This step helps control how the gel stain is absorbed and leads to a more uniform finish.

After staining, multiple coats of tinted lacquer are applied for durability and sheen. The result is a warm, consistent finish that enhances the natural beauty of the cherry.

Final Assembly and Installation

Once the finish is dry, all parts are assembled. Concealed hinges are installed using a jig, and drawer slides are added for smooth operation. The wine racks and glass holders are secured in place, completing the piece.

The finished cabinet is both functional and visually striking, with every component fitting neatly and working together as a cohesive whole.

Watch the full video and subscribe to Steve’s channel:

Matt’s Take

These are my personal thoughts and tips based on my own experience in the shop. This section is not written, reviewed, or endorsed by the original creator of this project.

Cherry is one of those woods that really rewards patience during the finishing process. That initial coat of shellac Steve uses is a smart move — cherry can be unpredictable with stain absorption, and that sealer coat helps even things out. Without it, you might end up with some areas that look much darker than others, especially around any grain reversals or figured sections.

The combination of plywood and solid wood accents is a practical approach that keeps costs reasonable while still delivering that premium look. Edge banding can be tricky at first — the key is getting your iron hot enough to activate the adhesive but not so hot that you scorch the veneer. A veneer trimmer makes quick work of the excess, but a sharp chisel works just fine too if you take light passes.

Safety-wise, those thin rip cuts for the wine slots deserve extra attention. Steve mentions using a thin rip jig, which is essential when you’re working with narrow pieces near the blade. Push sticks and featherboards are your friends here — never try to guide small pieces with just your fingers, no matter how confident you feel.

The SketchUp planning phase really pays dividends on a project like this with multiple components that all need to work together. Taking time upfront to work out the proportions and create a cut list helps avoid those frustrating moments when you realize something doesn’t fit quite right.