This video was created by Jodee from Inspire Woodcraft. It takes a closer look at a popular woodworking question—can MATCHFIT clamps be used in reverse, and if so, how well does it work?

At first glance, flipping the clamps might seem like a simple adjustment that could save space or streamline jig design. But as Jodee demonstrates, the reality is more complicated. The video breaks down the pros, cons, and physics behind the idea, offering insights that go far beyond surface-level tool use.

Watch the full video and subscribe to Jodee’s channel:

Overview of the Tapering Sled Design

The conversation stems from Jodee’s tapering sled, a straightforward jig designed for repeated, accurate cuts. The sled is built to last, and it incorporates MATCHFIT track-style clamps to hold the workpiece securely in place.

One key design choice is the narrow blade-side margin. This small lip of material prevents the clamps from extending into the blade’s path, protecting both the workpiece and the sled itself. It’s a subtle but important safety and durability feature.

Some viewers suggested reversing the clamps to avoid the need for that extra material. On paper, this approach might simplify the design, but Jodee explores why it doesn’t quite work in practice.

What Happens When You Flip the Clamps?

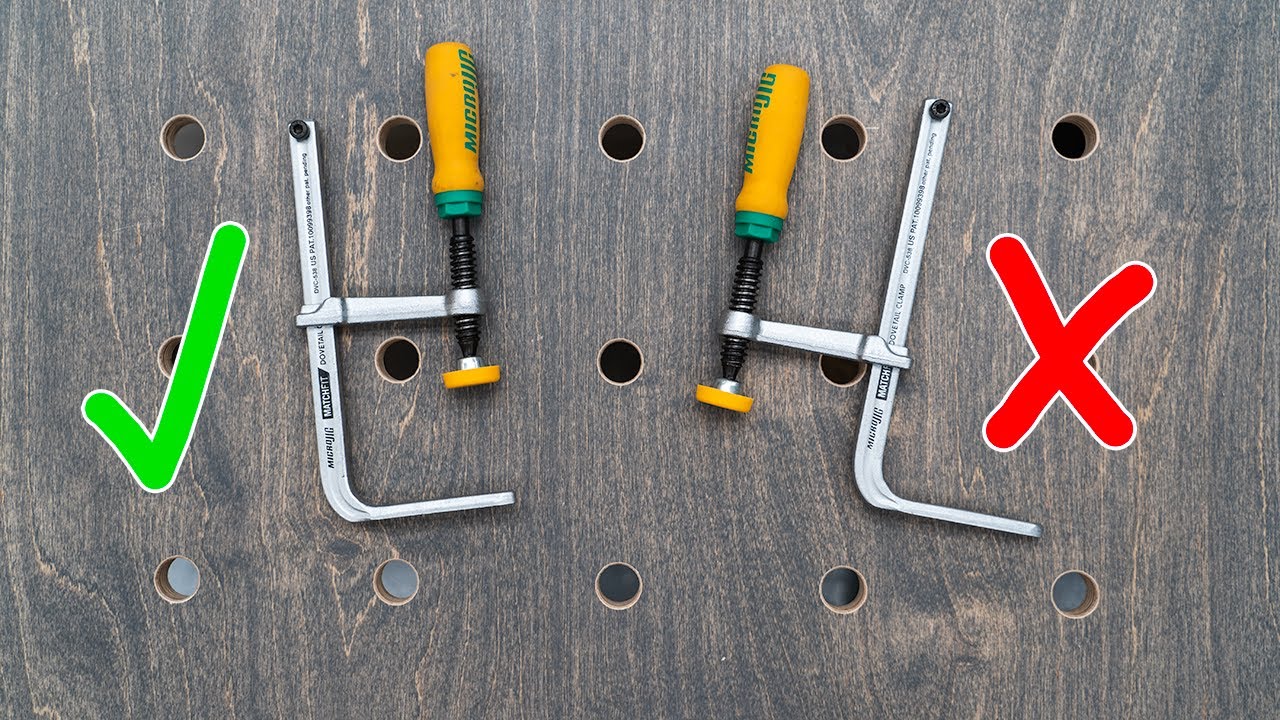

MATCHFIT clamps function best when the screw pushes the clamp foot up into the workpiece. This creates even, balanced pressure, helping hold material securely during a cut.

Reversing the clamps, however, changes that dynamic. The screw pushes down on the material, and the heel of the clamp lifts away from the surface. This creates uneven pressure, concentrating force on the rear of the clamp and risking damage to the sled or the workpiece.

Jodee experimented with this setup and found that it often led to weak clamping force. On narrower pieces in particular, the foot of the clamp would sometimes lose full contact, compromising the grip and stability during cutting.

Testing Design Alternatives

As part of the process, Jodee explored several possible tweaks to the jig design. One idea involved cutting grooves into the fence to seat the reversed clamps. But this led to another issue: the reversed clamp exerted so much pressure at the heel that it risked breaking or bending the support area.

To fix that, Jodee tried adding a strip of wood over the dovetail groove to offer more support. While this helped with pressure distribution, it introduced a new problem: the clamp could only be used in a fixed location.

That lack of adjustability defeated part of the MATCHFIT system’s appeal. In most setups, the ability to slide the clamp along the groove is essential for positioning based on the size or shape of the cut.

Widening the Fence: A Trade-Off

Another solution involved widening the fence of the tapering sled. Doing this would let the reversed clamp rest on more material, providing the surface needed to counteract the downward pressure.

But that change comes at a cost. A wider fence eats into the sled’s usable width, limiting the size of stock that can be cut. While it’s a workable compromise, it reduces flexibility in a way that might not be worth it for many woodworkers.

Jodee’s point is that every design change creates ripple effects. Finding the right balance between clamp support, workpiece clearance, and sled width takes thoughtful testing—not just guesswork.

Why This Matters for Woodworkers

This video isn’t just about clamps—it’s about how small design changes can impact the performance and safety of a jig. Reversing the clamps might save an inch of material, but if it undermines holding pressure or increases wear on your sled, the cost is greater than it seems.

Jodee walks through each variation with clear explanations and real-world testing, offering viewers a practical understanding of how clamping mechanics work. It’s a valuable example of how to think critically about workshop decisions rather than relying on assumptions.

Final Thoughts on the Reverse Clamp Trick

In the end, using MATCHFIT clamps in reverse might seem like a time-saver or design shortcut, but it introduces real performance issues. Uneven pressure, reduced clamp reliability, and increased wear on the sled all outweigh the potential benefits.

Jodee’s tapering sled remains effective with its original setup, and his willingness to test alternatives adds clarity for anyone building or modifying their own jigs. If you’re thinking about flipping your clamps, this video is worth a watch before making the change.

Support Jodee by visiting his online store here: https://inspirewoodcraft.com/collections/all.