This project was built and designed by Izzy Swan.

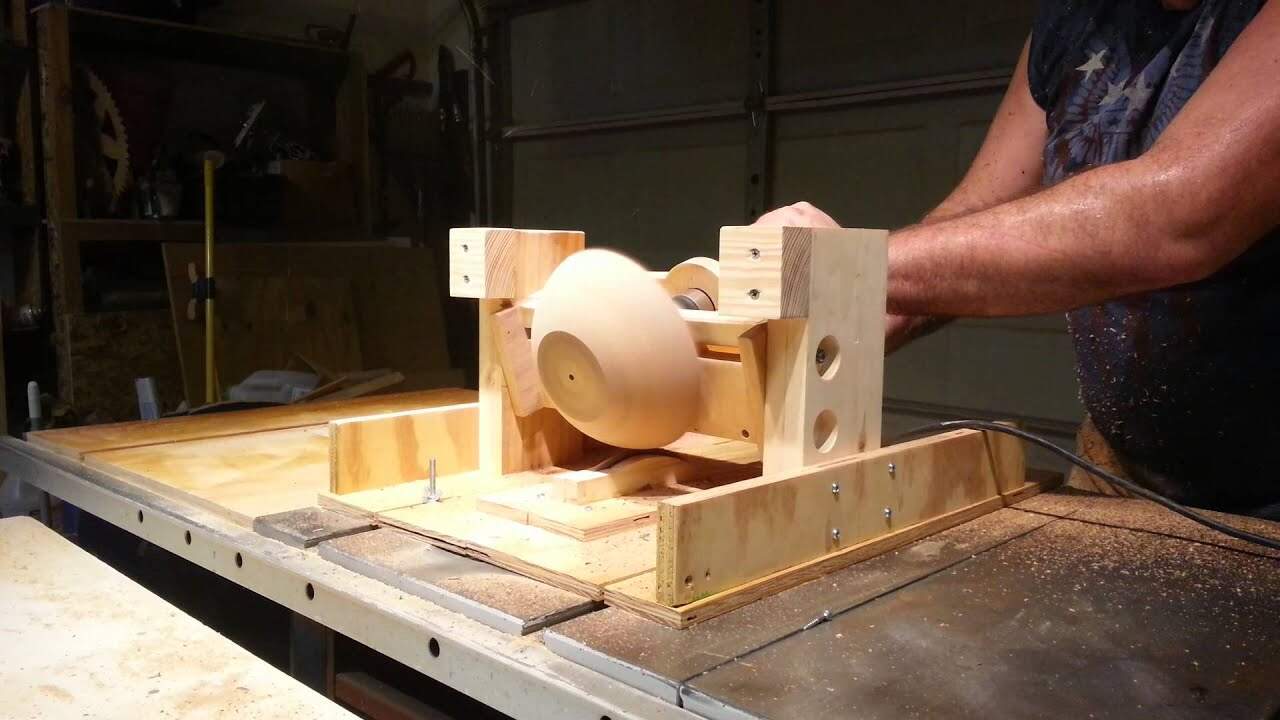

Izzy demonstrates a simple, purpose-built jig that allows a woodworker to turn both the outside and the inside of a wooden bowl on a tablesaw, turning a familiar tool into a small lathe-like setup for segmented or solid blanks.

Watch the full video and subscribe to Izzy Swan:

Design and Purpose

The jig is conceived as a single solution to handle both outside profiling and hollowing the interior of a bowl using the tablesaw as the primary cutting power.

The approach is experimental and approachable, showing how a stout, well-secured fixture can expand the capabilities of common shop equipment for bowl turning tasks.

Setup and Safety

Securing the blank and balancing it on the jig are the foundation of a safe and successful run, and Izzy emphasizes checking fasteners and alignment before spinning the assembly at speed.

He also highlights the inherent risk of repurposing machines and recommends only attempting similar setups when the operator fully understands their equipment and clamps the work extremely solidly.

Turning the Outside

For the exterior profile, the blank is mounted and the tablesaw blade is raised into the rotating work to shape the bowl’s outside, with careful attention to centering to minimize vibration.

Izzy notes that initial imbalance can cause vibration early in the cut, but a sturdy jig and good mounting will stabilize once some material is removed and the piece becomes more balanced.

Turning the Inside

The interior cup is made by reversing or repositioning the blank and using a different blade suited to hollowing, allowing a controlled approach to the internal profile without switching to a lathe.

Izzy demonstrates that matching blade choice and blade height adjustments let a builder experiment with wall thickness and interior shapes while staying within the tablesaw setup’s limitations.

Troubleshooting and Practical Tips

Balance the blank as well as possible before cutting and consider temporary braces or supports behind the work if extra security is desired, especially for segmented pieces with irregular density.

Expect vibration, plan for it by building the jig heavy and rigid, and be prepared to stop and rebalance if chatter persists; changes in blade size or blade height are useful levers for tuning results.

Finishing and Next Steps

After turning, simple finishing—oil or another surface treatment—helps reveal the bowl’s form and any natural features like knots that become focal points rather than flaws.

Izzy suggests experimenting with different blade sizes and settings to refine wall thickness and profile, and to treat the first runs as experiments to learn how the jig behaves with various blanks.

Why This Jig Matters

This jig demonstrates a resourceful way to extend the functionality of a tablesaw, offering a low-barrier method for makers who want to explore bowl turning without investing in a lathe right away.

The technique encourages careful setup, attention to balance, and iterative adjustments—skills that translate across many shop projects and help build confidence with nonstandard jigs.

Please support Izzy by visiting his website: https://www.izzyswan.com/.

Matt’s Take

These are my personal thoughts and tips based on my own experience in the shop. This section is not written, reviewed, or endorsed by the original creator of this project.

This kind of jig really showcases how creative thinking can expand what’s possible in a smaller shop. Using the tablesaw as a makeshift lathe is clever, though it definitely requires extra attention to setup and safety. The key here is that heavy, rigid construction Izzy mentions – any flex or movement in the jig will amplify into serious vibration problems once you’re spinning.

Balance is everything with this approach. I’d suggest taking time to rough-balance your blank before mounting – even removing obvious high spots with a hand plane can make a huge difference. Starting with slower blade speeds if your saw allows it can also help you feel out how the setup behaves before committing to full speed.

For anyone considering this technique, remember that unconventional setups like this demand extra respect for the tool. Your normal tablesaw safety habits still apply, plus you’re dealing with rotational forces that can catch you off guard. Keep your hands well clear of the spinning work, and don’t rush the cuts – let the blade do the work at its own pace.

The beauty of this jig is how it opens up bowl turning to folks who might not have space or budget for a dedicated lathe. It’s a great way to test whether you enjoy this type of work before making a bigger investment.