This video tip was shared by Billy from Newton Makes. It highlights a clever way to turn basic two-dimensional drawings into eye-catching three-dimensional components—especially useful for furniture parts like jewelry box legs.

With a simple design process and free software, this approach allows woodworkers to create consistent, repeatable shapes that elevate any project. Whether you’re new to templates or just looking for a better method, Billy walks through the process step-by-step to make it approachable for any skill level.

Watch the full video and subscribe to Billy’s channel:

Starting with a Digital Template

The process begins by designing a basic shape using vector-based software. Billy recommends Inkscape, a free and powerful tool ideal for creating detailed woodworking templates.

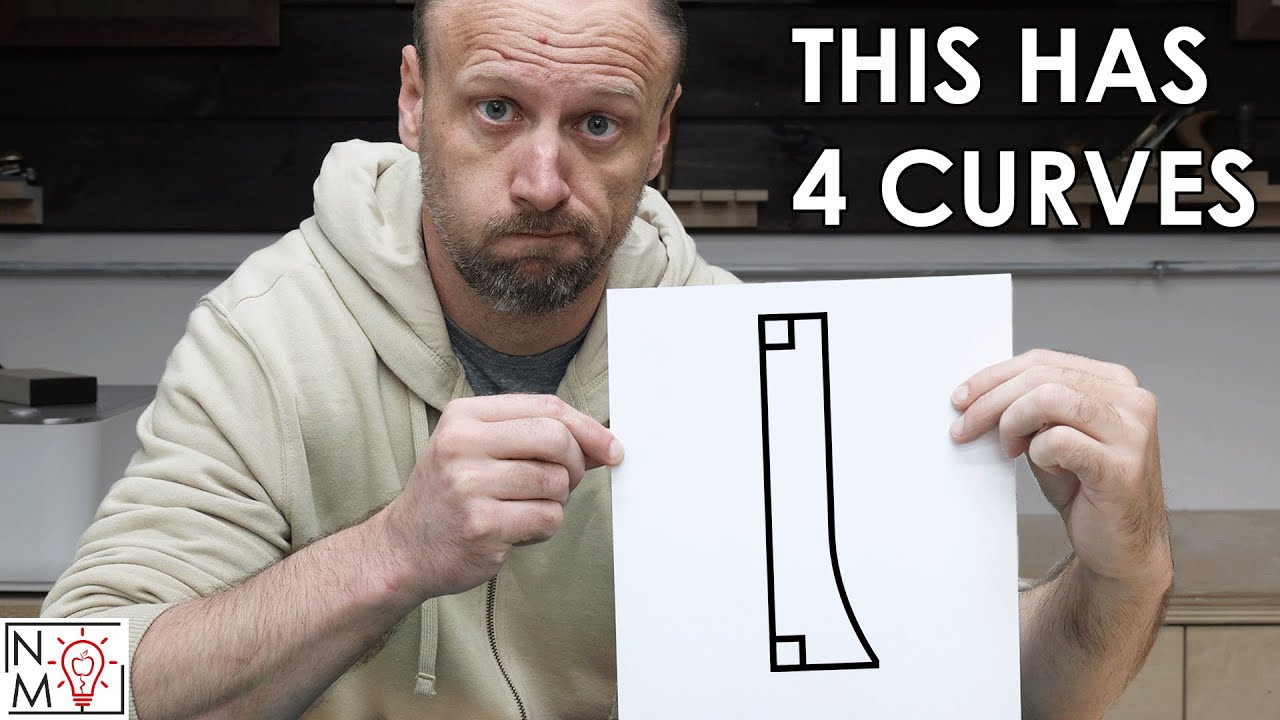

He starts by drawing a simple rectangle and then modifying it to introduce curves and form. This step lays the foundation for a component that can later be shaped into a clean, sculpted piece of joinery.

By duplicating shapes and modifying them individually, Billy creates depth and variation in the template layout. These initial sketches serve as the blueprint for transferring the design to wood.

Understanding Key Features in Inkscape

Billy introduces a few basic but essential functions in the software that help shape and refine the template. “Fill” adds color to objects for visual organization, while “Stroke” defines the outline of the shape.

Using “Path” tools, Billy converts objects into editable curves. This lets him adjust anchor points, move lines, and round out corners—features that are essential when building organic or sculpted designs.

The “Object” and “Duplicate” functions also play an important role in creating symmetrical patterns. These small tweaks make it easier to work precisely and iterate quickly on new design ideas.

Building and Organizing the Final Template

Once the rough shape is ready, Billy duplicates and color-codes different elements to keep track of each part. Visual clarity is important when working with layered shapes, and changing stroke colors helps avoid confusion during layout.

He also uses guides and rulers within Inkscape to align pieces with precision. These digital tools ensure that the real-world layout will be accurate once transferred to the material.

The final step in the design phase is using the “Fracture” tool. This separates intersecting lines into individual shapes, which can be reworked into new forms or adjusted based on design needs.

Transferring the Template to Wood

Once the digital template is complete, it’s printed and attached to the wood using spray adhesive and contact paper. Billy recommends applying contact paper to the wood first so the paper template can be removed cleanly without leaving behind sticky residue.

Accurate placement is key during this phase. He carefully aligns the printed design before committing with the adhesive, ensuring everything will line up once it’s time to cut.

This method not only saves time but allows for precise placement of complex curves and joints.

Cutting and Shaping the Component

With the template secured to the workpiece, Billy uses either a bandsaw or scroll saw to cut along the lines. For tighter curves and smaller details, he leans toward using a scroll saw for better control.

As he works through the cuts, Billy keeps the offcuts nearby. These pieces can be taped back into place if needed or reused for added shaping support. This tactic provides flexibility and helps prevent mistakes from becoming wasted material.

After rough shaping, the piece can be further refined with rasps, sanders, or hand tools depending on the project.

The Moment of Reveal

Once the shaping is complete and the template is peeled off, the finished piece is ready. Watching a simple design transform into a sculpted, three-dimensional object is one of the most rewarding parts of the process.

Billy demonstrates how this technique is especially effective for smaller furniture parts, like jewelry box legs, where curves and detail make a big difference.

Why This Method Works So Well

Templates offer two key advantages: repeatability and precision. Once a design is finalized, it can be reused over and over again—saving time and maintaining consistency across multiple parts.

For more complex shapes, this approach also eliminates guesswork. You know before you start cutting that the final shape will fit into the larger project correctly.

A Technique Worth Adding to Your Skill Set

This woodworking trick is more than a time-saver—it’s a way to improve both the design and build quality of your projects. Whether you’re adding legs to a keepsake box or shaping unique elements for a cabinet, templates offer control and flexibility that’s hard to match by eye alone.

Billy’s clear breakdown of the process makes it easy to follow along. It’s a great method for anyone who wants more confidence when working with curves, angles, and repeat shapes in wood.

Please support Billy by visiting his website here: https://www.newtonmakes.com/shop.

Matt’s Take

These are my personal thoughts and tips based on my own experience in the shop. This section is not written, reviewed, or endorsed by the original creator of this project.

Billy’s template approach really shines when you’re working on projects that need multiple identical parts. There’s nothing more frustrating than cutting four furniture legs by eye and realizing the third one doesn’t match the others. Digital templates take that guesswork completely out of the equation.

The contact paper trick is brilliant for template removal. I’ve seen too many woodworkers skip this step and end up scraping adhesive residue off their workpiece for way too long. That extra minute of prep saves you from a real headache later. When you’re positioning the template, take your time—once that spray adhesive makes contact, you’re pretty much committed to that placement.

For the cutting phase, don’t rush through those curves. Whether you’re using a bandsaw or scroll saw, let the blade do the work and stay just outside your line. You can always sand or rasp back to the line, but you can’t add material back once it’s gone. Keep those offcuts handy like Billy suggests—they’re perfect for providing support when you’re doing final shaping work.

The real beauty of this method is how it scales. Once you’ve got a template dialed in, you can bang out matching parts quickly and confidently. It’s especially valuable for those smaller decorative elements that can really make a piece stand out.