This video is by Norman Pirollo of WoodSkills.

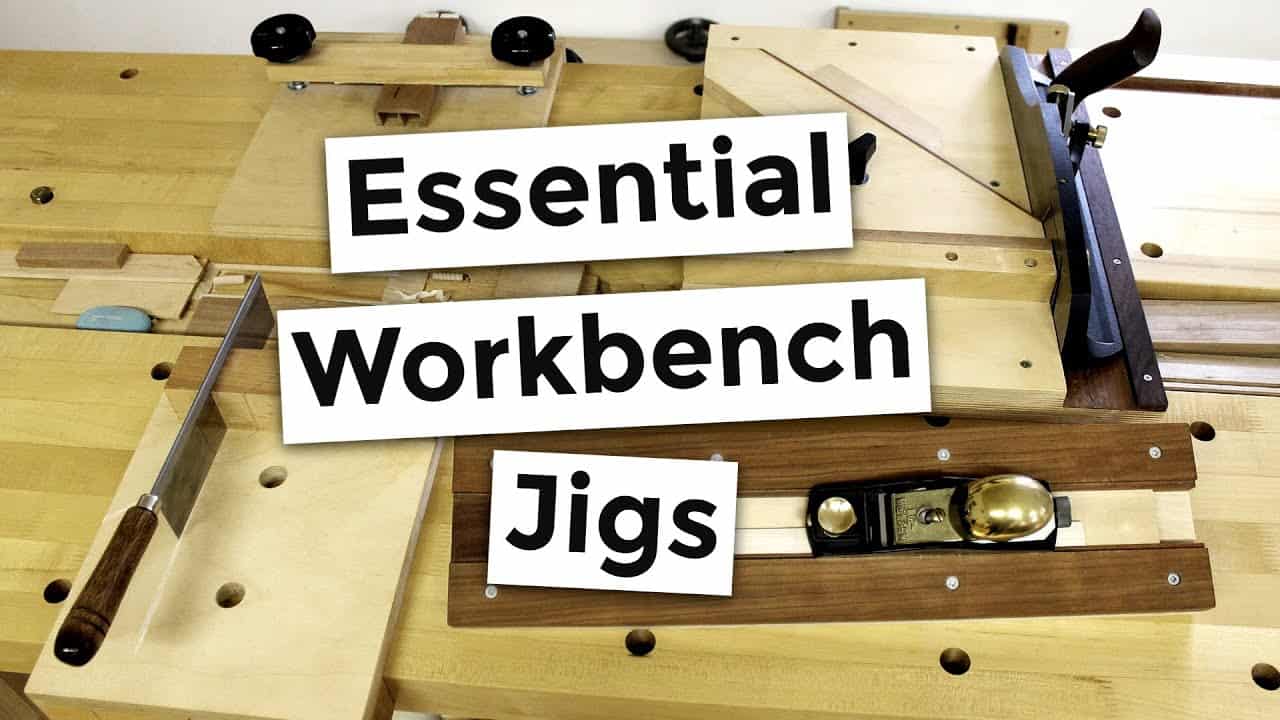

It highlights a set of simple, shop-ready jigs that improve accuracy, save time, and bring consistency to hand-tool workflows.

Instead of large machines or complex fixtures, Norman relies on a handful of bench appliances that are always within reach. These jigs support day-to-day operations like dovetailing, trimming, and thin strip preparation, offering immediate setup and precision without extra fuss.

Watch the full video and subscribe to Norman’s channel:

Why Bench-Top Jigs Matter

Workbench jigs—also called bench appliances—are meant to live on or near the work surface. Unlike larger fixtures or machine setups, these tools are lightweight, easy to store, and designed to work in tandem with planes, saws, and chisels.

The core advantage is speed. There’s no need to walk across the shop or dial in a fence for a one-off task. Norman’s approach favors minimal setup and maximum repeatability, making them ideal for furniture makers who value hand tool precision.

Four Go-To Jigs for Everyday Use

Norman demonstrates four jigs that he keeps close at hand: a thicknessing sled, a dovetail jig, a bench hook, and a shooting board. Each one solves a common challenge in hand-tool work and is built to be durable and dependable.

Together, these jigs allow fast repeatable tasks, clean finishes, and tight joinery—all with hand tools. Below is a closer look at how each one is built and used.

Thicknessing Sled for Uniform Thin Strips

The thicknessing sled holds stock in place while a block or smoothing plane rides along a fixed track. A spacer beneath the plane sets the final thickness of the strip, allowing the user to change dimensions simply by swapping spacers.

This jig is especially useful for preparing thin parts like lattice strips, small joinery stock, or decorative inlays. Norman customizes the length of the sled depending on the size of stock being processed and keeps a few sleds at his bench ready for use.

Correct grain orientation is important during planing, and the sled’s design helps reduce tear-out by controlling cut direction. It’s a time-saving jig that eliminates constant resetting of plane depth.

Dovetail Jig for Fast and Accurate Layout

Norman’s dovetail jig is a bench-mounted fixture that holds boards in place while laying out and cutting dovetails by hand. It features spring-loaded cleats and sandpaper faces that keep thin parts from shifting.

The jig acts as a sacrificial surface while also elevating the work for better ergonomics. Transfer lines are drawn using a saddle-style square, and waste is removed with a chisel directly on the jig.

By simplifying positioning and alignment, this jig cuts down on fussy setups and allows for efficient joint layout. Norman notes that with experience, the jig makes even repetitive dovetailing feel smooth and intuitive.

Bench Hook for Clean, Rock-Free Crosscuts

The bench hook is one of the most basic and useful hand tool jigs in the shop. Norman uses them for quick crosscuts with a backsaw, and he keeps one at each bench so they’re always nearby.

His version includes hardwood fences with pre-cut kerfs for 90° and 45° cuts. A dual-fence setup adds stability and prevents rocking, and some hooks are modified with dog holes to lock them in place using bench dogs.

When tuned correctly, a bench hook produces end grain so clean it often requires no additional finishing. It’s one of those shop-made tools that saves time every single day.

Shooting Board for Crisp Ends and Miters

Norman’s shooting board is a precision tool used with a hand plane to square end grain and cut miters. The board is tailored to fit a specific plane, ensuring the sole rides smoothly against the guide fence.

Modular attachments allow for case miters and face miters, giving the board more versatility. Some versions are left- or right-handed depending on user comfort and the direction of cut.

The shooting board is the final step in many furniture projects, used to clean up edges, square components, and produce flawless fits. Norman emphasizes the importance of building one that matches the tools you use most often.

Building and Using Jigs Effectively

Throughout the video, Norman shares tips that make a big difference in performance:

- Build multiples if you use several benches, so each one stays in place.

- Match the jig to the tool—don’t try to make one jig fit every plane or saw.

- Add replaceable faces using thin hardwood layers that can be swapped out as they wear.

- Integrate micro improvements like spring clamps, sandpaper for grip, and dog-hole compatibility to save setup time.

- Design for comfort and efficiency using hinged supports, flip-up squares, and one-handed operation wherever possible.

Why These Jigs Are Still Valuable in Modern Shops

Even in shops equipped with machines, these hand tool jigs provide advantages. They’re instantly available, don’t require setup time, and offer tactile control—especially when working with thin, fragile, or detailed parts.

Norman’s system shows that a well-prepared bench and a few smart jigs can rival even high-end equipment for small-scale furniture work. It’s a reminder that workflow matters as much as the tools themselves.

Support Norman by visiting his website: https://www.woodskills.com/

Matt’s Take

These are my personal thoughts and tips based on my own experience in the shop. This section is not written, reviewed, or endorsed by the original creator of this project.

What I love about Norman’s approach is how these jigs eliminate the mental friction that can slow down hand tool work. When your thicknessing sled is already set up and your bench hook is right there, you’re more likely to actually use them instead of trying to eyeball cuts or settle for “good enough.” That immediate accessibility makes a huge difference in both quality and efficiency.

The key insight here is matching jigs to your specific tools and workflow. A shooting board that’s perfectly sized for your favorite block plane will feel completely different than one that’s too big or small. Same goes for the thicknessing sled — if the track doesn’t match your plane’s sole width, you’ll fight it every time. Taking the time to dial in these details upfront pays dividends in daily use.

One thing worth noting about all these jigs is how they support your body mechanics. Working at bench height with proper support reduces fatigue and gives you better control over cuts. The spring-loaded cleats on the dovetail jig are particularly clever — they eliminate the constant battle with shifting workpieces that can throw off your layout lines and make clean cuts frustrating.

If you’re just getting started with hand tool jigs, I’d recommend beginning with a well-made bench hook. It’s simple to build, immediately useful, and teaches you the principles that apply to more complex jigs. Once you experience that satisfying feeling of a perfectly clean crosscut straight off the saw, you’ll understand why these simple tools are worth the shop space.