Izzy Swan demonstrated the test featured in this video.

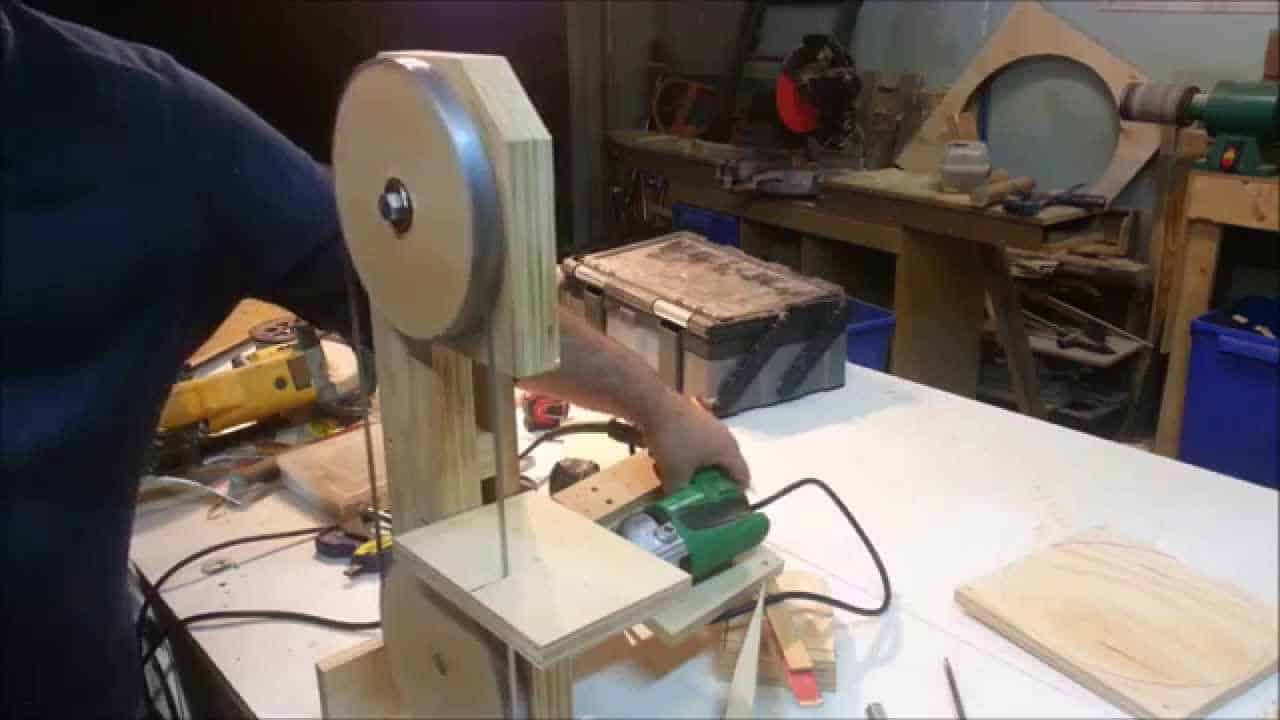

The video shows a quickly assembled, experimental bandsaw driven by a handheld drill to see whether a drill has enough torque and resilience to act as a prime mover for a small bandsaw setup.

Watch the full video and subscribe to Izzy Swan:

Design & Setup

The test rig is intentionally crude: a simple frame with bearings on the top and bottom wheels and a bolt through the lower hub to keep the rotation true.

The drill is used as the motor and mounted to drive the wheel directly, while the builder balances the wheels and adjusts the setup to minimize vibration before cutting.

Performance & Results

Initial cuts included thin plywood and common pine stock, progressing to thicker laminated pine and a sample of hardwood to push the drill harder.

The drill completed the cuts without overheating, though it showed signs of slowing and increased strain under heavier load, indicating a practical limit to thickness and continuous duty.

Practical Considerations

The makeshift machine lacked blade guides and precise bearings, which led to some vibration and a tendency for the blade to deflect when the operator pushed on the workpiece.

Mounting the drill squarely and adding proper guides and support would reduce friction and blade wander, improving cut quality and lowering stress on the motor.

Improvements & Next Steps

Adding adjustable blade guides, dedicated bearings, and a rigid motor mount are the most impactful upgrades to turn this prototype into a more reliable shop tool.

Longer-term, the concept points toward a multi-tool setup where a single drill could power a variety of jigs and small machines with quick-change mounts and better engineered power transfer.

Why This Test Matters

The experiment highlights how common, affordable tools can be repurposed for creative shop solutions and encourages makers to prototype before committing to custom builds.

It also underlines the importance of proper mechanical support and guidance when adapting handheld motors to stationary tasks to ensure safety, repeatability, and performance.

The drill-powered bandsaw test is a useful proof of concept for hobbyists interested in low-cost, multi-purpose shop setups and serves as a reminder that thoughtful iteration yields better results than a single rough trial.

Please support Izzy by visiting his website: https://www.izzyswan.com/.

Matt’s Take

These are my personal thoughts and tips based on my own experience in the shop. This section is not written, reviewed, or endorsed by the original creator of this project.

This kind of experimental approach really showcases the value of proof-of-concept builds before diving into a major project. What strikes me about this test is how it demonstrates both the potential and the practical limits of repurposing handheld tools for stationary work. The drill clearly has enough power for light-duty bandsaw operations, but the setup reveals where proper engineering makes the difference between a novelty and a useful tool.

The vibration and blade deflection issues really highlight why commercial bandsaws invest so much in rigid frames and precise blade guides. When you’re hand-holding a workpiece against a flexing blade, that’s where accidents can happen quickly. If someone wanted to develop this concept further, I’d prioritize blade guides and a proper fence system before worrying about motor upgrades.

From a safety standpoint, this kind of setup requires extra attention to workpiece control and body positioning. Without the stability of a proper table and fence, it’s easy to lose control of small pieces or put your hands in the wrong place. The experimental nature makes it interesting to watch, but anyone trying this should think through the safety implications of each cut.

What’s really valuable here is the methodical testing approach – starting with thin stock and progressively challenging the setup. That’s solid shop methodology that applies whether you’re testing a drill-powered bandsaw or sizing up any new tool for your specific needs.