This project was built and designed by Billy from Newton Makes. It’s a precision jig built to simplify and improve the process of making picture frames, turning a challenging task into a repeatable, efficient workflow.

Whether you’re a beginner or an experienced woodworker, this jig is a helpful addition to your shop. It offers clean, consistent results while saving time on measurement and setup.

Watch the full video and subscribe to Billy’s channel:

Why This Jig Stands Out

Making picture frames usually involves careful calculations and tricky angle cuts. The key benefit of this jig is that it eliminates most of that complexity.

Instead of using formulas to calculate inside and outside dimensions, you just set the stop block to the desired size. Once set up, every cut is repeatable and square, resulting in consistent, clean miters.

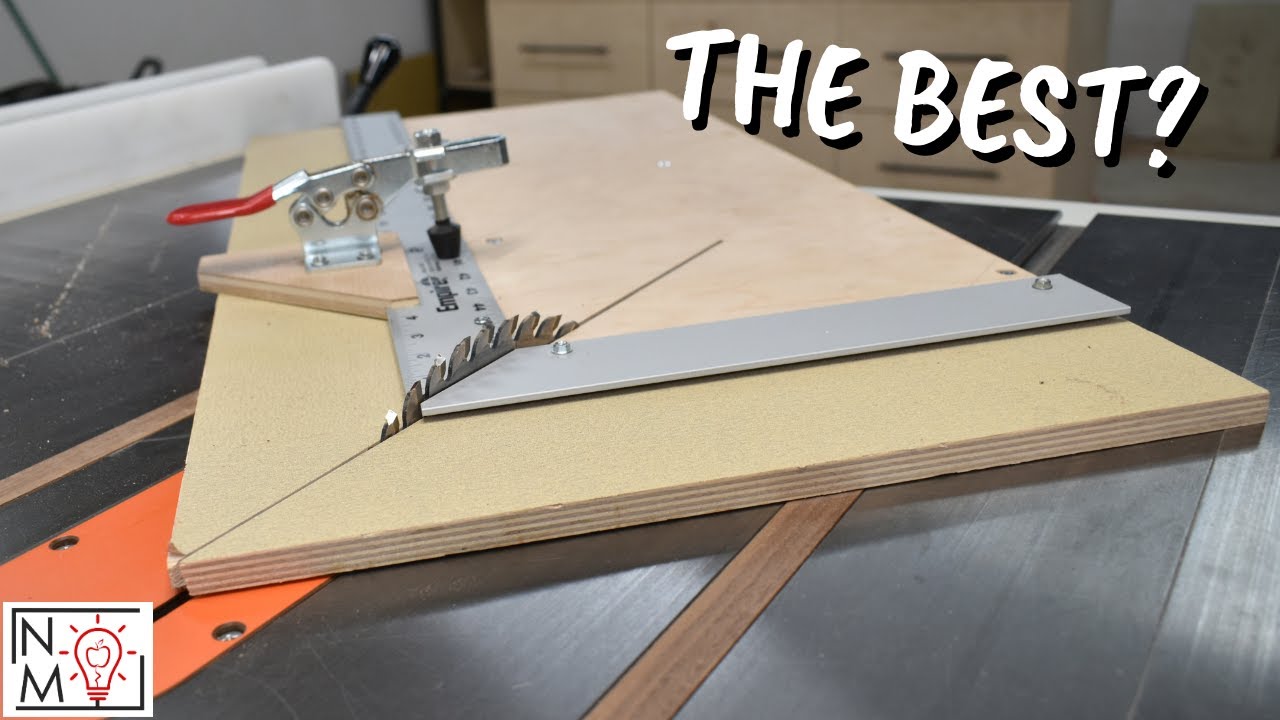

Core Components of the Jig

The jig is made from a few essential parts, each contributing to precision and repeatability. These include a flat plywood base, rails to ride in the table saw miter slots, a metal ruler for measurements, and a stop block to hold workpieces in position.

Each piece is easy to source and assemble. The real advantage lies in how they work together to guide your cuts with consistent alignment and accuracy.

Starting with the Base

The base is cut from sturdy plywood and sized to accommodate your workpieces comfortably. It doesn’t need to be oversized—just big enough to allow room for frame material and safe hand placement during cutting.

Rails are attached underneath the base to fit snugly into your table saw’s miter slots. These need to be straight and properly aligned to ensure the jig moves smoothly and tracks perfectly through each cut.

Aligning the Measuring Guide

A metal ruler is added to the top surface of the jig, acting as a built-in measurement tool. One end of the ruler is cut at a 45-degree angle to match the blade, creating a visual reference for aligning each piece.

The ruler must be mounted carefully so it runs perfectly parallel with the cutting line. A square or alignment block can help during this step. Accuracy here ensures that all future cuts fall exactly where intended.

Building and Adjusting the Stop Block

The stop block is the heart of the jig’s adjustability. It slides along the ruler, locking in the length of your frame pieces without needing to calculate interior or exterior dimensions.

Made from plywood, the block fits tightly under the ruler and can be clamped in place. Adjusting the stop block is simple and fast, making it easy to switch between frame sizes without recalibrating.

Boosting Grip and Stability

To keep workpieces from slipping while cutting, Billy recommends adding sandpaper to the jig surface. This provides grip without damaging the frame material.

The combination of a stable base, tight-fitting rails, and a non-slip surface creates a setup where pieces stay exactly where you want them—no shifting mid-cut and no guessing on alignment.

Using the Jig for Frame-Making

Once built, the jig allows you to cut each side of a frame with repeatable precision. Just line up your stock, clamp the stop block, and run the jig through the saw.

For frames with rabbets to hold glass or artwork, you can route the rabbet first, then use the jig to cut the miters. This sequence ensures that all four sides match perfectly, both in size and detail.

Each frame piece ends up with identical angles and lengths, which is critical for a tight-fitting miter. That’s one reason this jig is such a game changer—it brings a high-end result into reach for woodworkers at any level.

What Makes This Jig Worth Building

Beyond its usefulness, this jig is approachable and affordable to make. It doesn’t require advanced joinery or expensive hardware. In return, you get faster production time and better results on every frame you build.

The setup works particularly well for batch-making picture frames, such as for selling at craft fairs or gifting. Once dialed in, you can knock out matching sets without second-guessing measurements or blade angles.

A Smart Upgrade for Any Shop

Billy’s design is thoughtful, simple, and highly effective. It’s a project that solves a real woodworking challenge and improves workflow in a meaningful way.

Whether you’re framing art, photos, or mirrors, having a dedicated jig saves time and increases accuracy. It’s one of those shop additions that pays off with every use.

Please support Billy by visiting his website here: https://www.newtonmakes.com/shop.