This project was built and designed by Zach from Bear Mountain Builds.

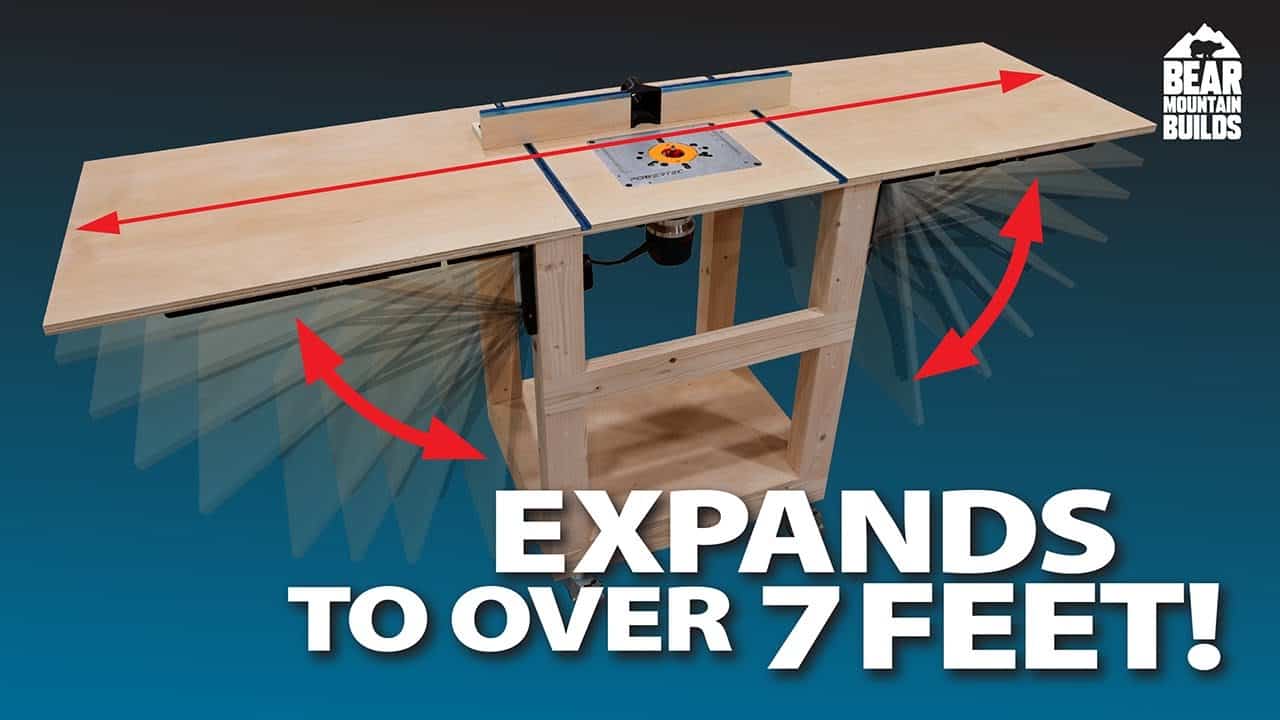

The video shows an expanding router table that folds compact for small shops and unfolds to support very long workpieces for safer, single-operator routing.

The build focuses on a sturdy frame, a universal router mounting plate, fold-down wings, integrated dust control, and an adjustable fence with T-track for stops.

Watch the full video and subscribe to Bear Mountain Builds:

Design and Purpose

The expanding router table is designed for makers who need big support but have limited floor space, folding down to a compact footprint when not in use. Zach emphasizes practical stiffness and safety by using a large, braced surface that distributes load through the wood and into the floor rather than relying solely on hardware.

The layout balances accessibility and capability; the router plate sits close to the front for easy bit changes while wings provide extra bracing for long stock. The overall approach is focused on functionality and shop ergonomics rather than decorative flourishes.

Lumber Prep and Frame

The frame is built from common dimensional lumber with the option to plane boards for a cleaner look, though the plans assume nominal sizes so a planer isn’t required. Zach runs through prepping the stock, cutting parts to length, and drilling pocket holes to simplify assembly and keep fasteners hidden.

Assembly relies on a simple, strong geometry: two matching halves joined by cross pieces and stretchers, with caster wheels added for mobility. The frame is designed to freestand and carry loads through lap joints for maximum stiffness.

Joinery and Assembly

Lap joints form the backbone of the structure, chosen because they transfer load through solid wood and are easy to lay out and clamp during glue-up. Pocket screws are used strategically to keep screw heads out of sight and to secure platforms and cross members where needed.

Zach shows techniques for clamping and squaring the assemblies, including using corner clamps and long clamps to keep cross pieces stable while driving screws. These simple shop methods make it approachable for hobbyists without specialized joinery tools.

Platforms and Router Mount

The top and bottom platforms are cut from plywood and notched to fit around the legs so they sit flush and register square to the frame. Zach explains a quick trick for tracing and cutting corner notches and how to use the platform to square the whole frame if pieces are slightly out of alignment.

Routing the opening for the router plate is done with a template to ensure precision and repeatability, with relief cuts first to make the trim-bit pass easier. The universal mounting plate drops into a recessed ledge and is leveled with set screws so the router bit can be made perfectly flush with the table surface.

Wings, T-Track, and Fence

Fold-down wings attach with heavy shelf brackets to increase support when expanded and fold cleanly when stored, giving a large, stable work surface for long stock. Zach covers practical tips for getting brackets parallel, pre-clamping an offcut ledge to hold the wing while positioning, and using washer-head screws to avoid shifting bracket position.

The fence is a modular assembly with integrated dust collection and T-track on the face for flip stops and accessories. Zach assembles the fence quickly with glue and brads, then mounts T-track on both the table and the fence so it’s flexible for jigging and repeatable cuts.

Dust Collection and Remote Control

Built-in dust control is a significant convenience on this table, centered behind the fence and tied into the table’s layout to capture chips at the bit. Zach also highlights a wireless outlet remote that lets the user turn the router on and off without reaching under the table, improving safety and accessibility.

The combination of a dedicated dust channel and an accessible on/off solution demonstrates a practical mindset: small improvements that reduce hassle and increase useability. These features make the router table feel more like a production tool than a hobby setup.

Using the Table

Zach demonstrates common router-table tasks—long straight rips, corner slotting, and flush trimming—and shows how the expanded surface makes one-person setups simple and secure. The larger surface minimizes cantilever and allows the operator to brace and guide long pieces with far less effort than a tiny tabletop would permit.

Dust collection performs well during these tests, and the T-track fence with flip stops streamlines repetitive work. The table turns challenging one-person operations into safe, repeatable cuts, which is the core advantage for small-shop builders.

Finishing and Add-Ons

Final surface treatment consists of a durable top coat and wax to improve slide and protection, making the table both pleasant to use and long-lasting. Zach mentions future add-ons such as an internal drawer system for bits and wrenches to increase storage and convenience inside the footprint of the table.

The plans and optional template/dust kit mentioned in the video make it easy to replicate the design, and the build leaves room for personalization based on individual shop needs or router choices. Practicality and upgradeability are central to the design philosophy.

Why this build matters

The expanding router table solves a common shop constraint by combining compact storage with a large, rigid work surface that supports long stock safely for single-operator use.

By focusing on simple, repeatable joinery, thoughtful layout, and practical features like dust control and a remote switch, the design raises the baseline for what a small-shop router table can do.

Get Zach’s plans here: https://www.bearmountainbuilds.com/products/expanding-miter-saw-table-copy.

Matt’s Take

These are my personal thoughts and tips based on my own experience in the shop. This section is not written, reviewed, or endorsed by the original creator of this project.

This expanding design is brilliant for shops where every square foot counts. The fold-down wings give you the best of both worlds — a compact footprint when stored, but serious support surface when you need it. That’s the kind of thinking that makes small shops work efficiently.

The lap joint approach for the frame is spot-on for this application. You get excellent load transfer through the wood itself rather than depending entirely on hardware, which matters when you’re dealing with the vibration and torque from a router. Those joints also help the table feel rock-solid, which builds confidence when you’re pushing long stock through.

I really appreciate the dust collection integration and that wireless remote switch — those are the details that transform a router table from functional to genuinely pleasant to use. Being able to flip the router on and off without crawling under the table is a safety win, especially when you’re handling awkward workpieces. The T-track on both the fence and table surface opens up a lot of jig possibilities too.

For anyone considering this build, that template routing approach for the router plate opening is worth the extra step. Getting that recess clean and consistent makes the difference between a professional feel and something that always bugs you every time you use it.