Grandpa’s tools didn’t come from a catalog. They came from his father. And his father’s father.

They were older than color TV, older than the interstate highway system, and somehow sharper than anything you could buy today.

No fancy coatings. No ergonomic handles. Just steel, wood, and decades of use that turned them into extensions of his hands.

These weren’t collector’s items gathering dust on a shelf. They were working tools—used daily, maintained religiously, and respected like family heirlooms.

Because that’s exactly what they were.

Modern tools break after a season. Grandpa’s tools? They’ve been cutting perfect joinery since before you were born—and they’ll be doing it long after you’re gone.

Here are 15 tools from his shop that proved age isn’t just a number. Sometimes, it’s a badge of honor.

A quick note: Every tool here is real—some I used myself, others I watched Grandpa wield with that quiet confidence only decades of experience can bring. I don’t have photos from those days, so I’ve done my best to recreate them with illustrations that honor their memory.

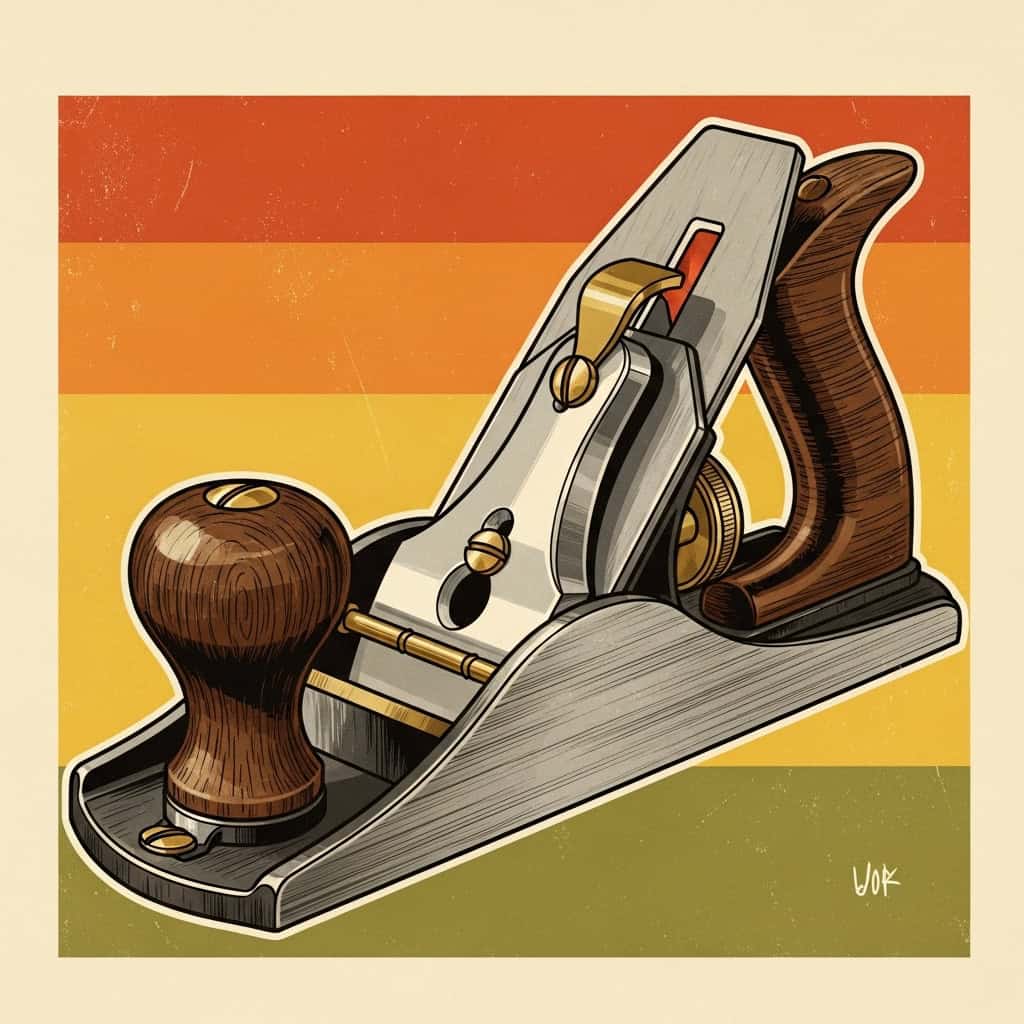

1. A Hand Plane From the 1940s That Still Takes Whisper-Thin Shavings

This wasn’t some boutique restoration piece. It was a working Stanley Bailey that Grandpa’s father used to build their house.

The sole was worn smooth as glass. The tote and knob were dark with decades of hand oil and sweat. The blade? Sharp enough to shave with.

He’d run it across a rough board and pull off shavings so thin you could read through them. One pass and the surface looked like it had been sanded to 400 grit.

Modern planes feel flimsy in comparison. Lighter. Cheaper. Like they’re trying to do the same job with half the conviction.

This one had weight. Presence. History.

You’d pick it up and immediately understand why Grandpa never bought a new one.

It didn’t need replacing. It was already perfect.

2. A Set of Chisels With Wooden Handles Worn Smooth as River Stones

The handles didn’t have varnish anymore. Just a deep, glowing patina from thousands of hours in Grandpa’s hands.

Some were socket chisels. Others were tang style. All of them were old enough to have been forged instead of stamped.

The steel held an edge longer than anything you’d find at the hardware store today. One sharpening session and they’d stay razor-sharp for months.

He had sizes from 1/4″ up to 2″—each one living in a specific spot on the bench, positioned exactly where his muscle memory expected it.

You’d try to use one and realize how much better the balance was. How the weight sat in your hand. How the edge bit into the wood with authority.

These weren’t tools. They were calibrated instruments that just happened to be older than your parents.

3. A Crosscut Hand Saw That Cut Straighter Than Your Circular Saw

It hung on the wall like a piece of art—long, elegant, with a handle that curved perfectly into your grip.

The plate had a gentle taper. The teeth were filed sharp and set just right. And when Grandpa used it, the sound was almost musical.

No binding. No wandering. Just smooth, straight cuts that needed zero cleanup.

He could rip through a 2×4 faster than you could set up a power saw. And the cut? Cleaner than most table saw blades.

“It’s all in the sharpening,” he’d say, running a file across the teeth with practiced rhythm.

Modern saws come sharp once. Then they’re disposable.

This one had been sharpened hundreds of times—and still had decades of life left.

4. A Marking Gauge Older Than Medicare

It was rosewood and brass, simple as a stone, and more accurate than a laser.

Just a wooden beam, a fence that slid along it, and a sharp pin that scored your cut line. No batteries. No calibration. No nonsense.

Grandpa would set it once and use it for an entire project—drawer after drawer, joint after joint, every measurement identical.

You’d check it with a ruler just to see. Dead on. Every time.

The wood was dark and smooth from use. The brass had that deep, burnished glow that only comes from decades of handling.

It probably cost three dollars new in 1955. Today? People pay ten times that for a vintage one in good shape.

Grandpa’s was in perfect shape. Because he never stopped using it.

5. A Combination Square That’s Still Dead Accurate

Heavy. Solid. Built like a tank.

The blade was thick steel with crisp markings. The head was cast iron or brass, depending on which one he grabbed.

No plastic. No flex. No wiggle.

You could set a bevel, check a corner, scribe a line, or use it as a depth gauge. One tool, a dozen jobs.

Modern squares feel like toys next to this thing. They’re lighter, cheaper, and they go out of square if you look at them wrong.

Grandpa’s? Still perfectly true after seventy years of being dropped, knocked around, and used daily.

He’d set it against a board, and you knew—knew—the line was right.

Because that square didn’t lie. It didn’t drift. It just worked.

6. A Brace and Bit That Made Holes Before Electricity Did

It looked like something from a museum—a U-shaped crank with a chuck on one end and a smooth wooden handle on top.

But grab it, load a bit, and start cranking? You’d understand why cordless drills didn’t kill it off for decades.

The leverage was incredible. The control was surgical. And the holes? Perfectly round, perfectly clean, with none of the tearout you get from a spade bit going too fast.

Grandpa had bits in every size—auger bits, Forstner bits, countersinks—all of them sharp, all of them stored in a wooden rack he built in the ’60s.

He’d drill through oak like it was pine, just turning that crank in smooth, steady circles.

No noise. No cords. No batteries to charge.

Just human power and perfectly engineered mechanical advantage.

7. A Spoke Shave That Could Fair a Curve Like Butter

Two handles, a short blade, and enough finesse to shape chair legs, tool handles, and rounded edges that looked like they’d been sanded for hours.

Grandpa’s was old—maybe 1930s, maybe older. The blade was worn down from decades of sharpening, but it still had plenty of life left.

He’d work it along a spindle, pulling toward himself in smooth, controlled strokes, and the wood would just melt away.

No sanding. No rasping. Just clean, flowing curves that felt as good as they looked.

Modern spoke shaves exist, but they’re either cheap and frustrating or expensive and boutique.

This one? It just worked. Because it had been working since before “mid-century modern” was a thing.

8. A Draw Knife That Could Hog Off Wood Like a Beaver

This thing was aggressive.

Two handles, a long curved blade between them, and the ability to remove more wood in one stroke than a hand plane could in ten.

Grandpa used it for rough shaping—taking bark off logs, chamfering edges, shaping tool handles from blanks.

You’d pull it toward you, and it would peel off thick ribbons of wood with a satisfying shwick sound.

It took skill. Pull wrong and you’d dig in, tear the grain, maybe take a chunk out of your project.

But in the right hands? It was a sculptor’s tool. Fast, powerful, and surprisingly precise.

His was old enough that the handles were worn into perfect custom grips. No two draw knives feel the same after fifty years of use.

And his felt right.

9. A Card Scraper That Turned Rough Wood Into Glass

It didn’t look like much—just a rectangular piece of spring steel, thin as a playing card, with a burr rolled onto the edges.

But hand it to someone who knew how to use it, and it was magic.

Grandpa would hold it at just the right angle, flex it slightly with his thumbs, and push it across a board. Fine dust would curl off the edge, and the surface would go from rough to mirror-smooth.

No sandpaper. No machines. Just steel and technique.

He’d use it on figured wood, tight spots, anywhere a plane might tear out the grain. And it never failed.

Modern scrapers are the same design. Because you can’t improve on perfect.

His had been resharpened so many times the edges were curved from wear. But it still worked flawlessly.

Some tools just don’t quit.

10. A Wooden Mallet Dense Enough to Be a Weapon

It was a chunk of lignum vitae—one of the hardest woods on earth—turned round, with a handle through the middle.

That thing weighed more than some hand planes. And it hit like a sledgehammer.

Grandpa used it for chiseling, knocking joints together, and “persuading” stubborn parts into place.

The head had dings, dents, and compressions from decades of striking steel. But it never cracked. Never split.

Because lignum vitae doesn’t care about your abuse. It just absorbs it and asks for more.

You’d try to use a modern rubber mallet after using his, and it felt like hitting things with a pool noodle.

His mallet had authority. Every strike landed with purpose.

And it would outlive your grandkids.

11. A Block Plane Small Enough to Pocket, Sharp Enough to Respect

Grandpa’s block plane lived in his apron pocket, always within reach.

It was tiny—maybe six inches long—but it could chamfer an edge, clean up a cut, or smooth a surface faster than you could grab sandpaper.

The blade was set at a low angle, perfect for end grain. The body was worn smooth. The adjustment wheel turned with buttery precision.

He’d pull it out mid-project, take two passes, and whatever rough spot you were staring at would just… disappear.

Modern block planes are hit or miss. Some are great. Most are frustrating.

His was broken in. Tuned. Known.

It didn’t fight him. It responded.

That’s what seventy years of daily use gets you.

12. A Coping Saw With a Frame That Refused to Bend

Thin blade. Deep throat. Infinite patience required.

Grandpa’s coping saw was older than fiberglass, and it cut curves that would make a scroll saw jealous.

The frame was solid—no flex, no twist. The blade tensioned perfectly with a few turns of the handle.

He’d cut dovetail waste, fretwork, interior curves—anywhere a bigger saw couldn’t reach.

The blade would sing as it cut, a high-pitched hum that meant you were doing it right.

Modern coping saws feel flimsy. The frames twist. The blades snap.

His didn’t. Because it was built back when “good enough” wasn’t good enough.

It just worked. Quietly. Precisely. Endlessly.

13. A Mortise Chisel Built Like a Pry Bar

This wasn’t a delicate paring chisel. This was a beast.

Thick, heavy, with a blade that could take a mallet beating all day without chipping.

Grandpa used it to chop mortises—deep, square holes for tenons. The kind of work that tests a tool’s spine.

The handle was ash or hickory, replaced once or twice over the decades but still perfectly fitted to the tang.

You could lean on this thing. Pry with it. Drive it into oak with a steel mallet and it wouldn’t flinch.

Modern chisels are thinner, lighter, “optimized.” Which means they’re weaker.

This one was over-built on purpose. Because when you’re chopping mortises by hand, there’s no such thing as overkill.

It was old. It was scarred. And it was indestructible.

14. A Try Square That Never Lied

Simple. Honest. True.

Just a wooden handle and a steel blade, joined at exactly ninety degrees. No moving parts. No adjustments.

Grandpa’s had been dropped, dinged, and used thousands of times. The wood was dark. The blade had surface rust in spots.

But check it against a known square? Perfect. Every time.

Because quality doesn’t drift. It doesn’t go out of true just because it’s old.

Modern try squares are often “close enough.” Off by a degree or two. Fine for rough work, terrible for precision.

His was exact. Because it was made when exact actually mattered.

You’d use it once and understand why he never bought another one.

It didn’t need replacing. It was already perfect fifty years ago.

15. A Bow Saw That Resawed Lumber Before Bandsaws Were Common

It looked medieval—a long, thin blade stretched in a wooden frame, tensioned with a twisted cord.

But grab the handle and start sawing? You’d resaw a board faster than you’d think possible.

Grandpa used it to split thick stock into thinner pieces, before bandsaws were in every shop.

The blade was narrow, flexible, and sharp. The frame kept it perfectly tensioned. And the cut was surprisingly clean.

It took technique. You couldn’t force it. You had to let the blade do the work, guiding it through in smooth, rhythmic strokes.

Modern bow saws exist, but most people don’t even know what they’re for anymore.

Grandpa’s hung on the wall like a relic. Except it wasn’t a relic.

He still used it. Because sometimes, the old way is just better.

Every one of these tools had decades on them. And every one still worked like the day it was made.

Maybe better. Because they were broken in. Tuned. Perfected through use.

Grandpa didn’t keep them because they were old. He kept them because they were good.

And good tools don’t have expiration dates.

They just keep cutting.