Woodturning is one of the most rewarding areas of woodworking, but it can also be frustrating if you start off with bad habits.

The right equipment, good technique, and solid safety practices will make your time at the lathe smoother and far more enjoyable.

These tips cover the fundamentals that every turner should know, whether you’re just getting started or looking to improve your skills.

1. Buy the right lathe

Your lathe is the single most important piece of equipment in woodturning, so it’s worth choosing wisely.

Many beginners focus on bed length, but swing capacity is usually what limits you first. You can always make small projects on a large lathe, but you can’t turn a large bowl on a small one.

Stability and build quality matter just as much as size. A heavier lathe reduces vibration and allows you to work more confidently.

If you plan to stick with woodturning long-term, investing in a lathe with room to grow will save you from outgrowing your machine too quickly.

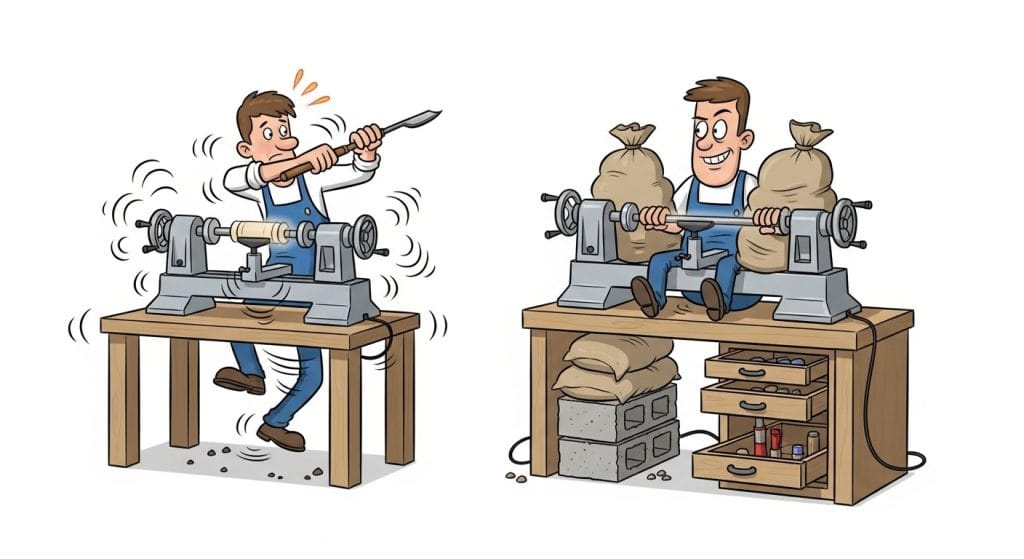

2. Stabilize your lathe

Even a high-quality lathe won’t perform well if it isn’t stable.

Lightweight lathes, especially mini and midi models, tend to vibrate when turning unbalanced blanks. Vibration not only makes it harder to control your tools but also leads to rougher surfaces and a higher risk of catches.

You can solve this by adding weight to your lathe stand with sandbags, concrete blocks, or storage drawers filled with heavy items.

Another option is to bolt your lathe securely to a sturdy bench or stand. By keeping the machine steady, you’ll get cleaner cuts, more accurate results, and a safer overall experience.

3. Choose the right wood

The wood you turn has a huge effect on how enjoyable the process will be.

Many beginners start with softwoods like pine because it’s cheap and easy to find, but softwoods tear out easily, clog your tools with sap, and can be discouraging to work with.

Hardwoods such as maple or oak provide a cleaner cut and give you better feedback as you learn tool control.

Green wood, which still contains moisture, is also easier to turn and is often used for rough-turning bowls before letting them dry.

Quality wood helps you focus on improving your technique instead of fighting the material.

4. Sharpen your tools often

Keeping your tools sharp is one of the most important habits in woodturning.

Dull edges require more force, which makes catches more likely and leaves rougher surfaces behind. Sharp tools glide through wood, producing cleaner cuts and reducing the amount of sanding you’ll need later.

You should sharpen before every session and again before making finishing cuts.

Depending on the species, you may need to touch up your edges multiple times while working, especially if the wood contains grit or mineral deposits.

Sharpening may feel like a chore, but it makes the process smoother, safer, and far more enjoyable.

5. Reposition the tool rest frequently

The tool rest is not something you set once and forget.

As you shape your piece, the distance between the tool and the rest increases, which reduces your leverage and makes the cut harder to control. By moving the tool rest frequently and keeping it close to your work, you reduce vibration and gain more stability in your cuts.

The height of the rest also matters — it should be positioned differently for gouges, scrapers, and other tools to keep the cutting edge at the right angle.

Paying attention to the tool rest gives you cleaner cuts and greater control throughout the project.

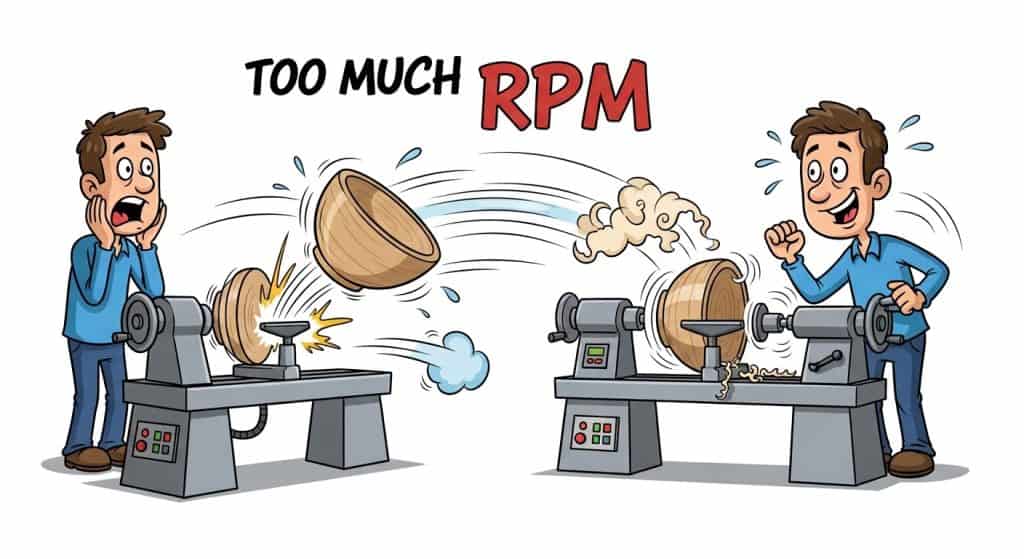

6. Respect RPMs

Lathe speed is critical to both safety and results.

Starting a lathe at high speed with an unbalanced blank can cause dangerous vibration or even send the piece flying. Always begin at the lowest speed and increase gradually once the blank is round and balanced.

A simple rule of thumb is to keep the diameter of your piece multiplied by RPM between 6,000 and 9,000. That means a 10-inch bowl should be turned at about 600 to 900 RPM, not thousands more.

Following this guideline keeps your turning safe, prevents accidents, and still allows you to achieve a smooth finish when you need higher speeds.

7. Don’t force the gouge

One of the most common beginner mistakes is forcing the tool through the wood.

A gouge is designed to slice, not pry, and pushing too hard can lead to chatter, catches, or a ruined surface. Instead, let the sharp edge do the work by making light, controlled passes.

Taking multiple shallow cuts is slower, but it produces a smoother finish and requires less sanding. It also keeps your cuts more predictable and reduces the strain on both your tools and your lathe.

The more you practice controlled cutting, the more natural it becomes to let the tool glide instead of forcing it.

8. Skip cheap tool sets

Those boxed chisel kits with a dozen tools may look tempting, but they are often designed for spindle turning and not for bowls.

Many of the tools in those sets have short handles that don’t give you the leverage you need for safe and accurate cutting.

Instead, start with one or two quality tools, such as a ½-inch bowl gouge, that can handle most of your turning tasks. Over time, you can add more specialized tools as your skills grow.

A single high-quality gouge will outperform a box full of poorly made chisels and help you build good habits from the start.

9. Use proper workholding

Securing your workpiece correctly is essential for both safety and precision.

Poor workholding can cause your piece to wobble, vibrate, or even fly off the lathe.

When cutting tenons, make sure they are the right length and that you create a flat shoulder so the chuck jaws seat firmly.

Always retighten the chuck after the first spin, since wood can shift slightly under the initial pressure.

10. Never use spindle tools for bowls

Spindle tools are designed for cutting with the grain on long, narrow pieces, not for the alternating end grain and side grain you encounter in bowl turning.

Using spindle gouges or roughing tools on bowls can overstress the tool, cause it to catch, or even snap under pressure. This can be dangerous and also ruin your workpiece.

Bowl gouges are built with the strength and geometry needed to handle the forces of bowl turning safely.

Stick with the right tools for the job, and save spindle tools for spindle work.

11. Always wear PPE

Safety gear should never be optional when you’re working at the lathe.

A full face shield protects you from flying debris, but it should always be paired with safety glasses underneath for full coverage.

A dust mask or respirator protects your lungs from fine particles, which can be harmful over time.

Avoid loose clothing, jewelry, and anything else that could catch in the lathe. Tie back long hair and wear sturdy footwear to protect your feet from falling tools or heavy blanks.

Making protective equipment part of your routine ensures you can enjoy turning without putting yourself at unnecessary risk.

Final Thoughts

The fundamentals of woodturning aren’t complicated, but they make all the difference in how safe and enjoyable the craft feels.

By choosing the right lathe, working with good wood, sharpening often, and respecting speed and tool use, you set yourself up for success.

Add in proper workholding and consistent use of safety gear, and you’ll avoid most of the problems that frustrate beginners.

Keep practicing these habits, and you’ll not only improve your results but also enjoy the process much more every time you step up to the lathe.